Super Duplex Steel S32750 / S32760 Fittings Supplier

Table Of Content

- What is Super Duplex Steel S32750 Fittings

- Standard Specification For Super Duplex Steel S32760 Fittings

- S32750 Super Duplex Steel Fittings Equivalent Grades

- ASTM A182, A815 Super Duplex Steel S32760 Fittings Types

- Chemical Composition of Super Duplex Steel S32750 & S32760 Fittings

- Mechanical Properties of SDSS S32750 Fittings

- Other Types of S32760 Super Duplex Steel Fittings Ready Stock

- ASME SA815, SA182 S32750 Super Duplex Steel Fittings Applications

- Searches Related to Super Duplex Steel S32760 Fittings

- Export Destinations for Super Duplex Steel S32750 Fittings

ASTM A182 S32750 Threaded / Screwed Fittings, SDSS S32750 High Pressure Forged Fittings, ANSI B16.11 Super Duplex Steel S32750, SAF 2507 Buttweld Fittings, SDSS 1.4410 Socket Weld Fittings, Super Duplex S32750 Fittings, ASTM A182 S32760 Pipe Fittings, UNS S32760 Pipe Fittings, SDSS 1.4501 Fittings, Super Duplex 2507 Seamless Pipe Fittings, Super Duplex Steel S32750 Fittings, UNS S32760 Fittings, Super Duplex Stainless Steel S32760 1D, 1.5D, 2D, 3D, 5D, 10D Bends, S32750 Super Duplex Stainless Steel Forged Fittings, S32760 Fittings Supplier in Mumbai, India.

Super Duplex 32760 Fittings at Navgraha Steel & Engg Company are specially designed and developed for extraordinarily corrosive and exceptional strength requisite applications. We offer these fittings in a variety of sizes and pressure ranges. It furnishes excellent corrosion resistance and oxidization prevention. These fittings are specified with thickness, dimensions, standards with a bending radius defined. These are also accessible in several components, including reducing elbow, stubend, pipe cap, union cross, and others. Therefore, it is easily obtainable with less expensive rates.

Why pick Super Duplex UNS NO32750 Fittings?

• Super Strength

• Anti-corrosive

• Crevice Strength

• Chloride Pitting Resistance

• Acid Corrosion Protected

• High Temperature Endurable

• Excellent Weldable

These are ideal corrosion-resistant to several environmental situations. In addition, it shows excellent efficiency in harsh corrosion solutions. These fittings also protect from acid corrosion in acetic and formic acid-containing mediums.

• What is Super Duplex UNS NO32750?

UNS NO32750 is Super Duplex grade of Chromium, Nickel, and Molybdenum alloy. It provides superior strength and outstanding corrosion resistance. In addition, it improves performance in chloride effect as well as thermal decay. At the same time, Super Duplex UNS NO32760 is highly alloyed in the range of Super Duplex Steel and proposed to apply in several hostile vicinity applications. Moreover, fittings is easily welded or also available with seamless and threaded types.

Super Duplex UNS NO32760 Fittings are widely used in extreme heat, revealing higher toughness to stress cracking effect. Also, it presents a wide range of adaptability of temperature, including cryogenic to very high value. Fittings can sustain long exposure to stress and temperatures. These fittings are essential in piping systems to connect system parts and allow a constant flow of fluid through them. Thus it effectively directs and controls flow in the system.

Super Duplex Steel S32760 Socket Weld Pipe Fittings, Super Duplex Steel S32750 Fittings Price, Super Duplex Steel S32750 Buttweld Elbow, SAF 2507 Unions, S32750 SDSS Long Stub Ends, S32750 SDSS Couplings, S32760 Super Duplex Steel Short Stub End, S32760 Duples Steel Forged Tee Stockist, Super Duplex S32750 1D, 1.5D, 2D, 3D, 5D, 10D Elbow, Grade S32750 SDSS Pipe Cross, SDSS S32760 Reducing Elbow, Super Duplex S32760 Pipe Nipple, Super Duplex S32750 Threaded Plug, SDSS S32750 Pipe Cap, Super Duplex Stainless Steel S32750-S32760 Reducers, SDSS S32750 Industrial Fittings Manufacturer in Mumbai, India.

Super Duplex UNS NO32750 Fittings are the best selected for super duplex qualities obtained with an austenitic-ferritic structure and higher Chromium value. Its high tensile strength sustains greater loads. Our Fittings are excellently durable and show outstanding functionality.

Applications of Super Duplex UNS 32760 Fittings:

• Desalination

• Pressure Vessels

• Fuel Gas

• Marine systems

• Heat Exchangers

• Chemical Processes

Standard Specification For Super Duplex Steel S32760 Fittings

| Specifications | ASTM A403 / ASME SA403, ASTM A182 & ASME SA182 |

| Forged Fittings Standards | ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799 |

| Buttweld Fittings Dimensions | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43 |

| Buttweld Fittings Size | 1/8” NB TO 48” NB. (Seamless & 100% X-Ray Welded, Fabricated) |

| Forged Fittings Size | 1/8” NB to 4” NB (Socketweld & Screwed-Threaded) |

| Buttweld Fittings Type | Seamless / Welded / Fabricated |

| Forged Fittings Type | Socketweld Fittings, Screwed-Threaded Fittings |

| Forged Fittings Class | 2000 LBS, 3000 LBS, 6000 LBS, 9000 LBS |

| Buttweld Fittings Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom |

| Buttweld Fittings Thickness | Sch 5s, Sch 10s, Sch 40s, Sch 80s, Sch 160s, Sch XXS |

S32750 Super Duplex Steel Fittings Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS |

| Super Duplex 2507 | 1.4410 | S32750 |

| Super Duplex 2507 | 1.4501 | S32760 |

Products Range of Super Duplex Steel S32750 / S32760 Fittings

Elbow

- Super Duplex Steel S32760 Elbow

- UNS S32760 Buttweld 10D Elbow

- SDSS S32760 Socket weld Elbow

- Super Duplex S32750 1.5D Elbow

- Super Duplex S32750 Seamless Elbow

- ASTM A182 Super Duplex S32750 Forged Elbow

- SDSS S32750 Welded Pipe Elbow

- Super Duplex Stainless Steel 1.4410 45 Degree Forged Elbow

- SAF 2507 Screwed / Threaded Elbow

- ANSI B16.9 SDSS S32760 Elbow

- Super Duplex Steel 1.4501 Reducing Elbow

- SAF 2507 2D Elbow

- SDSS 1.4501 Short Radius Elbow

- ASME SA815 S32760 Super Duplex Stainless Steel Pipe Elbow

- UNS S32750 90 Deg. LR Elbow

Tee

- Super Duplex Steel 1.4501 Unequal Tee

- ANSI B16.9 SDSS S32760 Tee

- Super Duplex Steel S32750 Seamless Tee

- SDSS S32750 Tee

- UNS S32760 Buttweld Tee

- ASTM A182 Super Duplex S32760 Forged Tee

- UNS S32750 Equal Tee

- Super Duplex Stainless Steel 1.4410 Reducing Tee

- SDSS S32750 Welded Pipe Tee

- Super Duplex Stainless Steel S32760 Tee

- SAF 2507 Screwed / Threaded Tee

- SAF 2507 Socket weld Tee

- Super Duplex Steel S32760 Tee

- ASME SA815 S32750 Super Duplex Steel Pipe Tee

- SDSS 1.4501 Forged Tee

Cross

- ASME SA815 S32750 Super Duplex Steel Pipe Cross

- SAF 2507 Welded Pipe Cross

- Super Duplex Stainless Steel 1.4410 Unequal Cross

- UNS S32760 Equal Cross

- Super Duplex Satinless Steel 1.4501 Reducing Cross

- Super Duplex Stainless Steel S32750 Seamless Cross

- SAF 2507 Screwed / Threaded Cross

- Super Duplex S32760 Cross

- Super Duplex Steel S32750 Cross

- SDSS 1.4501 Forged Cross

- ASTM A182 Super Duplex S32750 Forged Cross

- UNS S32750 Buttweld Cross

- SAF 2507 Cross

- SDSS S32760 Socket weld Cross

- ANSI B16.9 SDSS S32760 Cross

Pipe Cap

- SAF 2507 Pipe Cap

- ASME SDSS S32760 Super Duplex Steel Pipe Cap

- SAF 2507 Seamless Pipe Cap

- Super Duplex Stainless Steel S32750 Pipe Cap

- Super Duplex Stainless Steel 1.4410 Pipe End Cap

- Super Duplex Stainless Steel 1.4501 Buttweld End Cap

- SDSS S32760 Socket weld Pipe Cap

- UNS S32750 End Pipe Cap

- SAF 2507 Screwed / Threaded Pipe Cap

- Super Duplex 1.4410 Forged Pipe Cap

- ASTM A182 S32750 Forged Pipe Cap

- Super Duplex Steel S32760 Pipe Cap

- ANSI B16.9 SDSS S32750 Pipe Cap

- UNS S32760 Butt weld Cap

Reducers

- SAF 2507 Buttweld Pipe Reducer

- SDSS 1.4501 Concentric Reducer

- SDSS S32750 Reducers

- UNS S32750 Seamless Reducers

- Super Duplex Stainless Steel S32760 Reducers

- Super Duplex Stainless Steel S32750 Reducers

- ASME SA815 S32750 Super Duplex Steel Reducers

- UNS S32760 Butt weld Reducers

- Super Duplex Stainless Steel 1.4410 Buttweld Reducer

- ASTM A182 SAF 2507 Pipe Reducers

- Super Duplex 1.4410 Eccentric Reducers

- Super Duplex S32750 Reducers

- ANSI B16.9 SDSS S32760 Reducers

- S32760 Super Duplex Steel Reducers

Couplings

- SDSS S32750 Socketweld Couplings

- ANSI B16.11 SDSS S32760 Couplings

- ASME SA182 Super Duplex Steel S32750 Couplings

- Super Duplex Stainless Steel 1.4410 Half Couplings

- Super Duplex 1.4501 Threaded Coupling

- UNS S32760 Screwed Couplings

- S32750 Super Duplex Steel Couplings

- UNS S32760 Forged Couplings

- Super Duplex Steel S32760 Couplings

- Super Duplex S32750 Couplings

- SAF 2507 Couplings

- SDSS S32760 Couplings

- Super Duplex Stainless Steel 1.4501 Full Coupling

- ASTM A182 S32750 Pipe Couplings

Chemical Composition of Super Duplex Steel S32750 & S32760 Fittings

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | Fe |

| S32750 | 0.030 max | 1.20 max | 0.80 max | 0.035 max | 0.020 max | 24.00 – 26.00 | 3.00 – 5.00 | 6.00 – 8.00 | 0.24 – 0.32 | 58.095 min |

| S32760 | 0.05 max | 1.00 max | 1.00 max | 0.030 max | 0.010 max | 24.00 – 26.00 | 3.00 – 4.00 | 6.00 – 8.00 | 0.20 – 0.30 | 57.61 min |

Mechanical Properties of SDSS S32750 Fittings

| Grades | Density (g/cm 3) | Density (lb/in 3) | Melting Point (°C) | Melting Point (°F) |

| S32750 / S32760 | 7.8 | 0.281 | 1350 | 2460 |

Other Types of S32760 Super Duplex Steel Fittings Ready Stock

- SAF 2507 Forged Hex Head Plug

- SDSS S32750 Street Elbow Supplier

- Super Duplex 1.4410 Buttweld Fittings Dimensions

- ASTM A182 SDSS S32760 Screwed Fittings

- ASME SA815 Super Duplex S32750 Butt weld Stub Ends

- Super Duplex S32760 1D Elbow

- S32750 SDSS 5D Bends Dealer

- SDSS S32760 LR Buttweld Elbow

- Grade S32750 Super Duplex Stainless Steel Pipe Fittings

- Super Duplex S32760 Forged Fittings Supplier

- Super Duplex Stainles Steel S32750 U Bends

- ANSI B16.9 Super Duplex Steel S32750 Pipe Fittings

- A182 S32760 SDSS Barrel Nipple

- 1.4501 Super Duplex Steel Socket Weld Fittings

- Super Duplex S32760 90 Deg Buttweld Elbow

- S32760 Super Duplex Steel Socket Weld Reducer Insert

- ASME SA182 Super Duplex S32750 Threaded Fittings

- SAF 2507 Socket Weld Fittings

- Super Duplex Stainless Steel S32760 Square Head Plugs

- SAF 2507 Seamless Fittings Supplier in Mumbai

- Super Duplex Stainless Steel S32760 Fittings Wholesaler

- UNS S32760 Two Joint Fittings Supplier

- SAF 2507 Fittings Dealer in India

- ASTM A182 S32750 LR Buttweld Elbow

- SAF 2507 Super Duplex Forged Fittings

- Super Duplex Stainless Steel S32760 Fittings Supplier in India

- Super Duplex S32760 Fittings Manufacturer

- ASTM A182 S32750 SDSS Welded Pipe Fittings

- S32760 SDSS Buttweld Fittings

- Super Duplex S32760 Socketweld Pipe Fittings

- ASME SA182 SDSS S32750 Forged Pipe Fittings

- SAF 2507 BSP Threaded Fittings

- SDSS S32750 Forged Fittings Stockist

- Grade S32750 Super Duplex Stainless Steel Buttweld Pipe Fittings

- Super Duplex Stainless Steel S32750 Hex Head Bushings

- Super Duplex Stainless Steel S32750 10D Elbow

- ASTM A182 S32760 Fittings at Best Price in India

- ASME B16.11 Super Duplex 45 deg. Elbow

- Super Duplex Stainless Steel S32750 Long Radius Elbow

- Super Duplex Stainless Steel S32760 Fittings Stockists

- S32760 SDSS 2D, 3D, 5D Pipe Elbow

- SDSS S32760 3D Bends Supplier in India

- Super Duplex Stainless Steel S32760 Round Head Plugs

- Austenitic Super Duplex S32750 Fittings

- SDSS S32760 Buttweld Fittings Manufacturer

- SDSS 1.4501 Forged Fittings Exporter

- S32760 Super Duplex NPT Threaded Fittings

- SDSS 1.4501 SDSS 1.5D Elbow Exporter

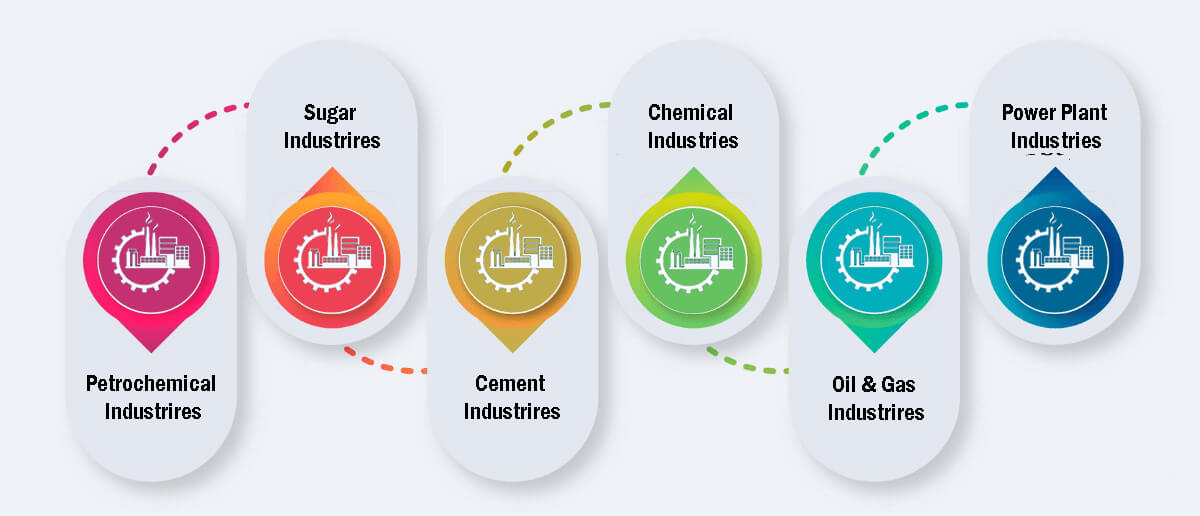

ASME SA815, SA182 S32750 Super Duplex Steel Fittings Applications