ASME SA 516 Grade 60 / 70 Boiler Quality Plates Supplier

Table Of Content

- What is ASME SA 516 Gr 60 Boiler Quality Plates

- Standard Specification For ASME SA 516 Gr 70 Boiler Quality Plates

- ASME SA 516 Gr 60 & 70 Boiler Quality Plates Types

- Tensile Requirements for Boiler Quality Steel Plates

- Chemical Composition of ASME SA 516 Gr 70 Boiler Quality Plates

- Mechanical Properties of ASME SA 516 Gr 60 Boiler Quality Plates

- Other Types of ASME SA 516 Gr 70 Boiler Quality Plates Ready Stock

- ASME SA 516 Gr 60 Boiler Quality Plates Applications

- Searches Related to ASME SA 516 Gr 70 Boiler Quality Plates

- Export Destinations for ASME SA 516 Gr 60 Boiler Quality Plates

ASME SA 516 gr. 70 Plates, boiler quality plate supplier, SA 516 Grade 60 Steel Plate, ASME SA 516 Carbon Steel Grade 60 Boiler Quality Plates Cut to Size, ASME SA 516 Gr 60 Boiler Quality Sheets, ASME SA 516 Gr 60 Boiler Quality Sheets, ASME SA 516 Grade 70 BQ Plates Exporter, Supplier & Stockist in Mumbai, India.

Navgraha Steels proudly offers a comprehensive range of SA 516 GR 70 and 516 GR 60/70 Boiler Quality Plates, meticulously crafted to meet the highest standards in the industry. SA 516 GR 70 and BQ 516 gr 60/70 Plates boast exceptional mechanical properties, including impressive tensile strength, yield strength, hardness, and elongation. Crafted with a precise blend of manganese, sulfur, silicon, and phosphorus, SA 516 Grade 60 Steel Plates exhibit outstanding resistance to corrosion and oxidation, even at elevated temperatures. The carefully balanced chemical composition ensures remarkable ductility and toughness, making them ideal for demanding applications.

Notably, including carbon in these plates results in a lower melting point, enhancing their durability and malleability. SA 516 Gr. 70 Plate and BQ 516 gr 60/70 Plates are primarily applied in welded pressure environments where notch toughness is critical. ASME SA 516 steel plate grade 60 encompasses a wide range of tensile strength and hardness, offering versatility in various industrial settings.

Boiler Quality Plates SA 516 GR 60/70 are well acclaimed for their mechanical properties like tensile strength, yield strength, hardness and elongation. These plates are made from some of the important components such as manganese, sulfur, silicon and phosphorus and they offer the best corrosion and oxidation at high temperatures. Further, the carbon content improves their strength and ductility, and they are suitable for pressure vessel applications requiring notch toughness.

The Boiler Steel Plates have relatively high flexibility, hardness, and toughness because of the accurate chemical makeup. These plates are widely used in industries that require materials for use under high performance especially in welded pressure vessels.

We are one of the best SA 516 Gr 70 plate manufacturers in Mumbai, offering Carbon Steel Plates designed to suit the requirements of several applications that involve high pressure and temperature. Because of these plates, the performance is assured and they may last for a long time that is why many industries use them.

SA516 Grade 65 Steel Plate, SA 516 Gr.60/70 Pressure Vessel Plates, BQ 516 gr 60/70 , SA516 Grade 60 Boiler Quality Plates Stockist, ASME SA 516 Gr 70 Hot Rolled Boiler Quality Plates, Carbon Steel Gr.60 BQ Plates, Carbon Steel Gr.60 Boiler Quality Plates Price, SA 516 gr 70 , A516 Gr 70 Boiler Quality Plate, A516 Grade 60 Pressure Vessel Steel Plates, SA 516 GR 70 Plate Supplier in Mumbai, ASME SA 516 Gr.60 Industrial Boiler Quality Plates Manufacturer in Mumbai, India.

Furthermore, SA 516 GR 70/60 Boiler Quality Plates are engineered to ensure efficient heat distribution, enabling them to excel even in harsh conditions. Their smooth surfaces and robust structures make them reliable performers under challenging circumstances. They exhibit resilience against stress corrosion cracking and crevice corrosion, even in severe weather conditions, making them a preferred choice.

Additionally, these plates are designed to resist acid attacks in elevated environments. SA 516 GR 60/70 Boiler Quality Plate adheres to strict quality standards with minimal phosphorus, sulfur, and residual elements. Subject to high-temperature heat treatment and hot and cold working processes, these plates are tailored to deliver exceptional performance across diverse applications.Choose Navgraha Steels for SA 516 GR 60/70 Boiler Quality Plates that exemplify quality, durability, and resilience in every facet of their performance. That our plates are impact tested at – 46 degree Celsius.

Specification of ASME SA 516 GR 70 Boiler Quality Plates

| Standard | ASME SA 516 / ASME SA 516 |

| Grade | Gr 60 / Gr 70 |

| Thickness | 3 mm to 200 mm |

| Width | 1250mm to 4000mm |

| Length | Up to 20,000 mm |

| Certification | DUAL CERTIFICATION [SA 516 GR. 60 / 70] TRIPLE CERTIFICATION. [SA 516 GR. 60 / 65 / 70] IBR AND NON IBR |

| Application | Pressure Vessel Plate, Boiler Quality Plate |

Products Range of ASME SA 516 GR 60 & GR 70 Boiler Quality Plates

Sheets

- ASME SA 516 Gr.60 Boiler Quality Sheet

- SA 516 Carbon Steel Gr 70 Boiler Quality HR Sheets

- SA516 Grade 60 Boiler Quality Steel Sheets

- ASME SA 516 Gr.70 BQ Steel Sheet

- SA516 Grade 60 Pressure Vessel Steel Sheets

- ASME SA 516 Gr 60 / 70 Boiler Quality Sheets

- A516 Grade 60 Carbon Steel Boiler Quality Sheet

- SA516 Gr 70 Carbon Steel Hot Rolled BQ Sheets

- ASME SA 516 Gr.60 Pressure Vessel Steel Sheets

Plates

- ASME SA 516 Gr.60 Boiler Quality Plate

- SA 516 Carbon Steel Gr 70 Boiler Quality HR Plates

- SA516 Grade 60 Boiler Quality Steel Plates

- ASME SA 516 Gr.70 BQ Steel Plate

- SA516 Grade 60 Pressure Vessel Steel Plates

- ASME SA 516 Gr 60 / 70 Boiler Quality Plates

- A516 Grade 60 Carbon Steel Boiler Quality Plate

- SA516 Gr 70 Carbon Steel Hot Rolled BQ Plates

- ASME SA 516 Gr.60 Pressure Vessel Steel Plates

Tensile Requirements for Boiler Quality Steel Plates

| Tensile Strength (ksi) | Tensile Strength (MPa) | Yield Strength (ksi) | Yield Strength (MPa) | Elongation in 200mm(%) | Elongation in 50mm(%) | |

| A516 Grade 55 | 55-75 | 380-515 | 30 | 205 | 23 | 27 |

| A516 Grade 60 | 60-80 | 415-550 | 32 | 220 | 21 | 25 |

| A516 Grade 65 | 65-85 | 450-585 | 35 | 240 | 19 | 23 |

| A516 Grade 70 | 70-90 | 485-620 | 38 | 260 | 17 | 21 |

Chemical Composition of ASME SA 516 GR 60 Boiler Quality Plates

| Grades | C | Si | Mn | P | S | Al | Cr | Cu | Ni | Mo | Nb | Ti | V |

| A516 Gr 60 | 0.18 | 0.4 | 0.95/1.50 | 0.015 | 0.008 | 0.02 (Min) | 0.3 | 0.3 | 0.3 | 0.08 | 0.01 | 0.03 | 0.02 |

| A516 Gr 70 | 0.18 | 0.4 | 0.95/1.50 | 0.015 | 0.008 | 0.02 (Min) | 0.3 | 0.3 | 0.3 | 0.08 | 0.01 | 0.03 | 0.02 |

Mechanical Properties of ASME SA 516 GR 70 Boiler Quality Plates

| Tensile strength (ksi) | Yield strength (ksi) | Elongation min, % 200 mm (8 in) | Elongation min, % 50 mm (2 in) |

| 485-620 (70-90) | 260 (38) | 17 | 21 |

Ready Stock of ASME SA 516 GR 60 Boiler Quality Plates

- Grade 60 / 70 Carbon Steel BQ Plates Manufacturer

- A516 Grade 60 Boiler Quality Plates

- ASME SA 516 Grade 70 BQ Steel Plates Supplier in Mumbai

- A516 Gr 60 Boiler Quality Plates Supplier

- A516 Carbon Steel Grade 70 Boiler Quality Plates Stockists

- SA 516 CS Gr.60 BQ Steel Plate Dealer in India

- ASME SA 516 Gr.60 / 70 Pressure Vessel Steel Plates

- SA516 Gr.60 Carbon Steel HR Sheets Supplier

- ASME SA 516 Grade 70 Boiler Quality Plates Exporter

- SA 516 Gr 60 / 70 BQ Plates Supplier

- ASME SA 516 Gr 60 Steel Plate

- SA 516 Gr 60 / 70 BQ Plates

- SA 516 Gr.60 Boiler Steel Plates Manufacturer

- ASME SA 516 Gr.60 Plates at Best Price in India

- A516 Grade 60 Boiler Quality Steel Plates

- ASME SA 516 Gr 70 Carbon Steel BQ Plates Supplier in India

- ASME SA 516 Grade 60/70 Plates Cut to Size

- A516 Gr.60 Boiler Quality Plate Supplier in India

- Carbon Steel A516 Gr.70 Class 70 Boiler Quality Plates Supplier

- ASME SA 516 Gr 70 Boiler Steel Plates

- SA 516 Grade 60 Boiler Quality Steel Plates Wholesaler

- A516 Gr 60 Carbon Steel BQ Plates

- ASME SA 516 Grade 70 Boiler Steel Plates Dealer

- SA516 Grade 60 / 70 BQ Plates

- ASME SA 516 Grade 70 Boiler Quality Steel Plates Stockist

- A516 Gr.60 Pressure Vessel Steel Plates

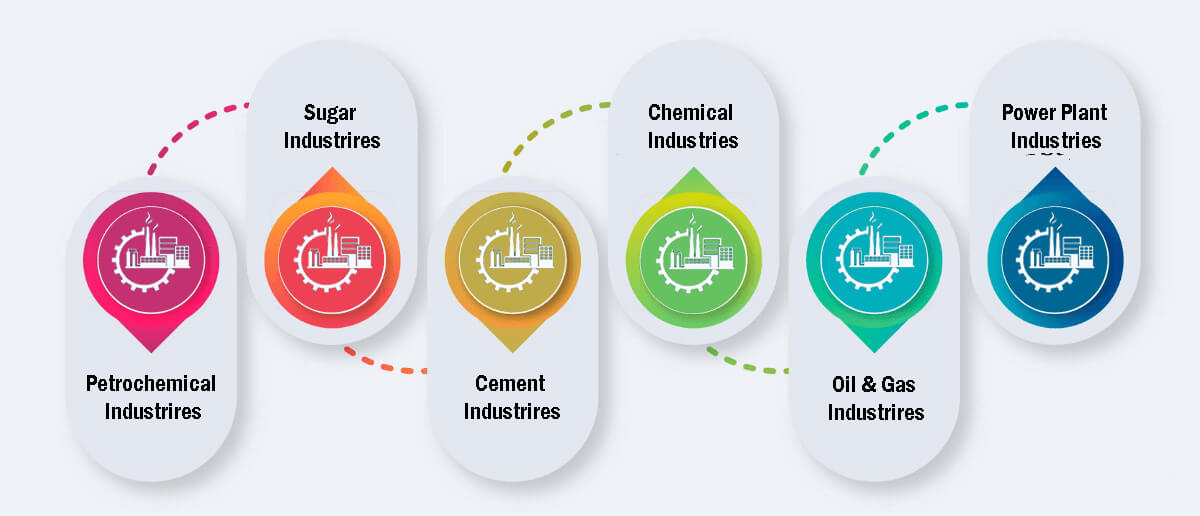

ASME SA 516 GR 70 Boiler Quality Plates Applications and Uses

Searches Related to ASME SA 516 GR 60 Boiler Quality Plates

Export and Supply Destinations of ASME SA 516 GR 70 Boiler Quality Plates

Countries where we export ASME SA 516 GR 60 & 70 Boiler Quality Plates

Cities where we export ASME SA 516 GR 60 And 70 Boiler Quality Plates

PRODUCTS

- Inconel / Incoloy

- Hastelloy

- Monel

- Nickel

- Alloy 28

- Alloy 20

- Stainless Steel

- Duplex Steel

- Super Duplex Steel

- Alloy Steel

- Mild Steel / Carbon Steel

- Special Products

- Other Grades