Abrasion Resistance Steel 500 Plates Supplier

Table Of Content

- What is Abrasion Resistance Steel 500 Plates

- Standard Specification For Abrasion Resistance Steel 500 Plates

- Abrasion Resistance Steel 500 Plates Types

- Chemical Composition of Abrasion Resistance Steel 500 Plates

- Mechanical Properties of Abrasion Resistance Steel 500 Plates

- Other Types of Abrasion Resistance Steel 500 Plates Ready Stock

- Abrasion Resistance Steel 500 Plates Applications

- Searches Related to Abrasion Resistance Steel 500 Plates

- Export Destinations for Abrasion Resistance Steel 500 Plates

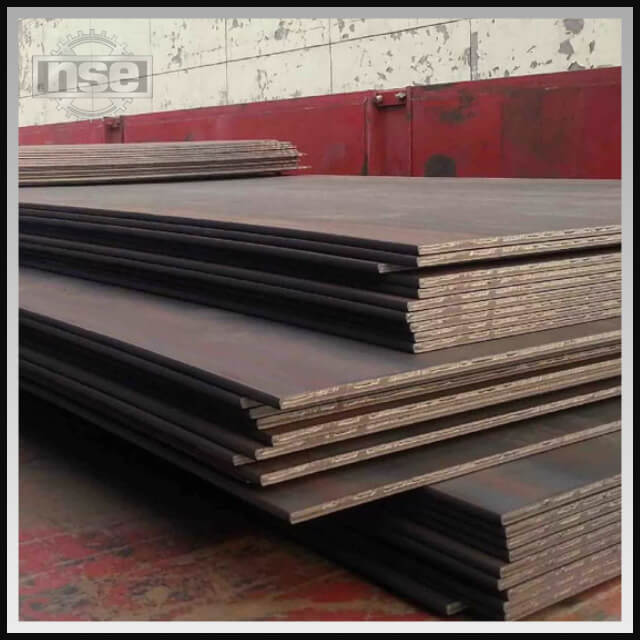

Brinell Abrasion Resistant Steel Plates, ABREX 500 Wear Resistance Plates Cut to Size, AR 500 Wear Plates, Rockstar Plates, JFE EH Plates, Abrasion Resistance 500 Plates, Abrasion Resistance Steel Plates, Abrasion Resistant Steel - AR 500 Plates, AR500 Steel Plate, Abrasion Resistance Steel 500 Plates, Abrex Plates Supplier, AR Plates, AR 500 Plates, 500 Wear Abrasion Resistant Plates Supplier in Mumbai, India.

Abrasion Resistant 500 steel, or AR 500 plate, is designed to withstand harsh conditions, offering an extended service life and exceptional toughness. Due to its superior resistance to crushing, high-speed impact from sharp and rough materials, and durable properties, abrasion-resistant steel plates are in high demand. For instance, a heated AR 500 plate with a 100mm thickness can be heated up to 175°C. Preheating varies depending on the thickness, with lower temperatures required for thinner plates.

Our Aggression Resistant 500 Steel plates are:

• Weldability

• High impact resistance

• Grain refinement

• The true attributes of cold bending

• After hardening treatment, long service life.

Cold bending makes it easier to fabricate machinery and components, and these plates can be customized for worn parts, significantly reducing machine erosion. A standout feature is that wear parts made from abrasion-resistant steel offer twice the hardness of standard steel.

These plates are sought after for their wear-resistant qualities and offer an impressive blend of corrosion resistance, good weldability, machinability, toughness, temperature and pressure resistance. Their toughness, strength, and hardness enable them to withstand severe wear. AR 500 plates can be easily welded, drilled, milled, and cut using standard workshop techniques. Typical applications include cutting edges, hoppers, truck liners, ore scrapers, screen liners, and conveyor buckets.

Abrasion Resistant Hot Rolled Steel Plates, Rockstar 500 Wear Resistant Sheet Plates, Abrex Plates, Abrex 500 Plates, 500 Wear Steel Plates, JFE EH 500 Abrasion Resistance Steel Plates, JFE EH 500 Steel Sheets, Abrasion Resistance Steel 500 Plate Price, AR500 Steel Plate, Rockstar 500 Steel Plates, 500 Abrasion Resistance Steel Plates Stockist, Abrex 500 Wear Resistant Steel HR Plates, 500 Abrasion Resistance Industrial Steel Plates Manufacturer in Mumbai, India.

The characteristics of wear plate 500 are as follows:

These plates are used because of wear resistance property. Also, these plates display an amazing combination of high resistance to corrosion, good weldability, machinability, strong structure, high toughness, high temperature resistance, pressure resistance, etc. Moreover, the combination of properties like toughness, strength, hardness is making it stand up to high wear. Abrasion Resistant 500 plates are rough, and they can be welded, drilled and milled and cut using ideal standard workshop techniques. These plates are used for cutting edges, hoppers, truck liners, ore scrapers, screen liners, conveyor buckets, etc.

Typical applications of Abrasion Resistant 500 Plates:

• Mining machine

• Earthmoving machinery

• Heavy ware platforms

• Industrial hoppers, funnels and feeders

Specification of Abrasion Resistant 500 Steel Plates

| Thickness | 5mm to 150mm |

| Width | 1,500mm to 2,500mm |

| Length | 6,000mm to 12,000mm |

| Heat Treatment | N, Q+T |

| Surface Paint | EP, PE, HDP, SMP, PVDF |

| Materials | Abrasion Resistant/ Abrex/ rockstar/JFE |

Products Range of Abrasion Resistant 500 Steel Plates

Abrasion Resistant Abrex Plates

- AR Abrex 500 Plates Manufacturer

- AR Abrex 500 Plates

- Abrasion Resistant Abrex HR Steel Plates

- Abrasion Resistant Abrex 500 Hot Rolled Steel Plates

- Abrasion Resistant Abrex 500 Plates Supplier

- Abrasion Resistant Abrex 500 Plates Stockist

- Abrex 500 Wear Resistance Plates

- AR 500 Abrex Wear Plates in India

- AR500 Abrasion Resistant Abrex Steel Plate

Abrasion Resistant Rockstar Plates

- Abrasion Resistant Rockstar 500 Plates Supplier

- AR 500 Rockstar Wear Plates in India

- Abrasion Resistant Rockstar 500 Hot Rolled Steel Plates

- AR500 Abrasion Resistant Rockstar Steel Plate

- Rockstar 500 Wear Resistance Plates

- Abrasion Resistant Rockstar HR Steel Plates

- AR Rockstar 500 Plates

- Abrasion Resistant Rockstar 500 Plates Stockist

- AR Rockstar 500 Plates Manufacturer

Abrasion Resistant JFE Plates

- AR 500 JFE Wear Plates in India

- JFE 500 Wear Resistance Plates

- AR JFE 500 Plates Manufacturer

- Abrasion Resistant JFE HR Steel Plates

- AR JFE 500 Plates

- Abrasion Resistant JFE 500 Plates Supplier

- Abrasion Resistant JFE 500 Plates Stockist

- AR500 Abrasion Resistant JFE EH Steel Plate

- Abrasion Resistant JFE 500 Hot Rolled Steel Plates

Chemical Composition of Abrasion Resistant 500 Steel Plates

| PLATE | C | Si | Mn | P | S | Cr | Ni | Mo | B | CEV | CET |

| THICKNESS MM | MAX % | MAX % | MAX % | MAX % | MAX % | MAX % | MAX % | MAX % | MAX % | TYPV | TYPV |

| 4-13 | 0.27 | 0.7 | 1.6 | 0.025 | 0.01 | 1.0 | 0.25 | 0.25 | 0.004 | 0.49 | 0.34 |

| (13) -32 | 0.29 | 0.7 | 1.6 | 0.025 | 0.01 | 1.0 | 0.50 | 0.30 | 0.004 | 0.62 | 0.41 |

| (32) -40 | 0.29 | 0.7 | 1.6 | 0.025 | 0.01 | 1.0 | 1.00 | 0.60 | 0.004 | 0.64 | 0.43 |

| (40) -80 | 0.30 | 0.7 | 1.6 | 0.025 | 0.01 | 1.50 | 1.50 | 0.60 | 0.004 | 0.74 | 0.46 |

Mechanical Properties of Abrasion Resistant 500 Steel Plates

| Thickness | Hardness HBW | Typical yield strength MPa, |

| mm | min – max 1) | not guaranteed |

| 4 – 32 | 470 – 530 | 1250 |

| (32) – 103 | 450 – 540 | 1250 |

Ready Stock of Abrasion Resistant 500 Steel Plates

- 500 Brinell Abrasion Resistant Steel Plates Supplier

- ABREX 500 Wear Resistance Plates Manufacturer

- Abrasion Resistant Rockstar 500 HR Sheets Supplier

- abrasion Resistant Abrex 500 Equivalent Plates

- abrasion Resistant Rockstar 500 Equivalent Plates

- AR 500 Plates Supplier in India

- JFE EH 500 Wear Plates

- Rockstar 500 abrasion Resistant Steel Sheets

- abrasion Resistant Steel 500 Sheets

- 500 Wear Plate Dealer

- abrasion Resistant 500 Plates

- Abrasion Resistant (AR) Plates at Best Price in India

- AR500 Steel Plate Supplier in Mumbai

- Abrasion Resistant Plates Cut to Size

- AR500 Rockstar Steel Plates Supplier

- Abrex 500 Wear Resistant Plates Stockist

- AR500 Plates

- Abrasion Resistant JFE EH 500 Plate Supplier in India

- AR500 Rockstar Plates Stockists

- abrasion Resistant JFE EH 500 Equivalent Plates

- Abrex 500 Wear Resistant Plates Sheets

- JFE EH 500 Plates Dealer in India

- Abrasion Resistant Steel – AR 500 Plates Exporter

- Abrasion Resistant Steel Rockstar 500 Plates Wholesaler

Abrasion Resistant 500 Steel Plates Applications and Uses

Searches Related to Abrasion Resistant 500 Steel Plates

Export and Supply Destinations of Abrasion Resistant 500 Plates

Countries where we export Abrasion Resistant 500 Plates

Cities where we export Abrasion Resistant 500 Steel Plates

PRODUCTS

- Inconel / Incoloy

- Hastelloy

- Monel

- Nickel

- Alloy 28

- Alloy 20

- Stainless Steel

- Duplex Steel

- Super Duplex Steel

- Alloy Steel

- Mild Steel / Carbon Steel

- Special Products

- Other Grades