Monel 400/ K500 Sheets / Plates / Coils Supplier

Table Of Content

- What is Monel 400/ K500 Sheets

- Standard Specification For Monel 400/ K500 Plates

- 400/ K500 Monel Sheets / Plates / Coils Equivalent Grades

- ASTM B127 Monel 400/ K500 Coils Types

- Chemical Composition of Monel 400/ K500 Sheets

- Mechanical Properties of Monel 400/ K500 Plates

- Other Types of 400/ K500 Monel Coils Ready Stock

- ASME SB127 400/ K500 Monel Sheets Applications

- Searches Related to Monel 400/ K500 Plates

- Export Destinations for Monel 400/ K500 Coils

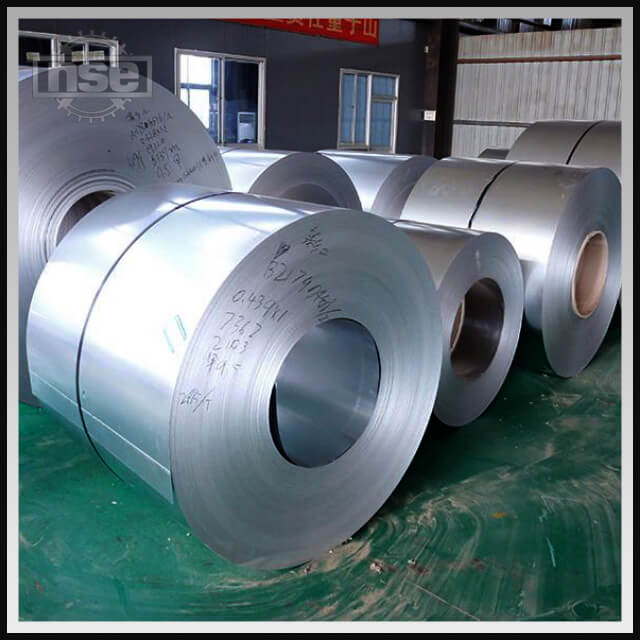

Monel K500 Plates and Sheets Cut to Size, Monel 2.4360 Coil, UNS N04400 Sheets, Monel® Alloy 400 Sheets, Monel 2.4375 Sheets, K500 Alloy Plate, Monel Alloy 400 Sheet, Monel N05500 Coils, ASTM B127 Monel Alloy K500 Coils, ASME SB127 Monel K-500 Sheet, Monel Alloy 400 Coils, Monel 400 Plates, Monel 400 Coils Supplier in Mumbai, India.

These Monel 500 plates show the durability of the highest quality of industry-standard products. Monel 400 sheet is a yielding Nickel-Copper alloy by means of its resistance to an extensive range of corrosive states of affairs.

Monel 500 Sheets is a nickel-copper alloy that combines the exceptional corrosion resistance of Alloy 400 in the company with the additional benefits of better hardness and strength. Meanwhile, these Monel 500 coils can be further customized in terms of sizes and thicknesses as per specific requirements given by our esteemed clients. These coils are valued for their very easy installation. It is a sheet and plate that can easily be hardened by the cold working process.

Therefore, the machinability of these sheets and plates is somewhat difficult because they require hardness during processing. The product is very strong and has a yield strength of approximately three times, that of the tensile strength, which is about double.

K500 Monel Plates, ASTM B127 Monel® Alloy 400 Hot Rolled Sheets, UNS N04400 Monel CR Plates, Monel K500 Sheets & Plates, 400 Monel Alloy Circle, Monel Alloy 400 Shim Sheets Stockist, Monel K500 Foils, Monel 2.4360 Perforated Sheet, Monel Alloy 400 Perforated Sheets, K500 Monel Chequered Plates, Alloy K500 Strips, Monel K-500 Industrial Sheets, Grade K500 Monel Alloy Coils, Plates & Coils Manufacturer in Mumbai, India.

The property of resistance is also there; it is resistant to rust. At the same time, these pipes are resistant to all kinds of acidic solutions. With their good strength qualities, the monel 400 coils are used in various industries, such as construction, industrial work, and petroleum departments. The main customers, especially the metallurgical industry, are mainly engaged in the development and manufacturing of structures. Some of the valuable features of the Monel 500 coils are their durability, finish, and correct dimension.

Standard Specification For Monel 400/ K500 Plates

| Specifications | ASTM B127 , ASME SB127 |

| Dimensional specification | JIS, AISI, ASTM, GB, DIN, EN, etc |

| Width | 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc/td> |

| Thickness | 0.3 mm to 120 mm |

| Form | Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Perforated Sheet, Chequered Plate, Strip, Flats, Blank (Circle), Ring (Flange) etc. |

| Value Added Services | Cutting, Beveling, Polishing, Threading, Destructive, Non Destructive, Ultrasonic Testing |

| Outside Finish | Finish as per customer Requirements |

| Delivery Condition | Annealed and Pickled, Polished, Bright Annealed, Cold Drawn |

| Packing | Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests |

| Specials | Sizes and Specifications other than above can be on request |

400/ K500 Monel Plates Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Monel 400 | 2.4360 | N04400 | NW 4400 | NA 13 | МНЖМц 28-2,5-1,5 | NU-30M | NiCu30Fe |

| Monel K500 | 2.4375 | N05500 | – | – | – | – | – |

ASTM B127 Monel 400/ K500 Coils Types

Sheets

- Monel Alloy 400 Sheets

- UNS N04400 Shim Sheet

- Monel 2.4360 Sheet

- Monel 2.4375 Sheets

- ASME SB127 Monel K500 Sheets

- Monel N04400 HR Sheets

- Alloy K-500 Hot Rolled Sheets

- Monel® Alloy 400 CR Sheets

- Monel N05500 Sheets

- Monel 2.4360 Cold Rolled Sheets

- Monel Alloy 400 Sheets

- Monel K500 Sheets

- ASTM B127 Monel 400 Sheet

- Monel Alloy K500 Sheet

Plates

- Monel 2.4360 Plates

- Monel N04400 Plates

- Monel K500 CR Plates

- Monel 2.4375 Cold Rolled Plates

- ASTM B127 Monel 400 Plate

- Monel Alloy N04400 HR Plates

- Alloy 400 Plates

- Monel Alloy 400 Plate

- Monel® Alloy K500 Hot Rolled Plates

- Monel UNS N05500 Plate

- ASME SB127 400 Monel Plates

- Monel K500 Plate

- Monel Alloy 400 Plates

- Monel 400 Plates

Coils

- Monel Alloy 400 Coil

- Monel UNS N04400 Slit Coil

- Monel 400 Coils

- Monel N05500 HR Coils

- Monel 2.4375 Coils

- Monel Alloy N04400 Coils

- Monel Alloy K-500 CR Coils

- Monel K500 Hot Rolled Coils

- Monel 2.4360 Cold Rolled Coils

- ASTM B127 Monel 400 Coil

- Alloy K500 Coils

- Monel ® Alloy 400 Coils

- ASME SB127 Monel Alloy K500 Coils

- Monel 2.4375 Shim Coils

Chequered Plate

- Monel 2.4360 Chequered Plate

- Monel 2.4375 Chequered Plates

- Monel K500 Hot Rolled Chequered Plates

- Monel 400 CR Chequered Plates

- Monel Alloy K500 Chequered Plates

- Monel UNS N04400 Chequered Plate

- Monel 2.4375 Cold Rolled Chequered Plates

- ASTM B127 Monel K-500 Chequered Plate

- 400 Monel Alloy Chequered Plates

- Monel Alloy N05500 Chequered Plates

- Monel ® Alloy Chequered Plate

- Alloy K500 Chequered Plates

- ASME SB127 400 Monel Chequered Plates

- Monel N05500 HR Chequered Plates

Perforated Sheet

- UNS N05500 Monel Perforated Sheet

- Monel Alloy N04400 HR Perforated Sheets

- Monel N05500 Perforated Sheets

- Alloy K500 CR Perforated Sheets

- 400 Monel Perforated Sheets

- ASTM B127 Monel 400 Perforated Sheet

- Monel Alloy 2.4360 Cold Rolled Perforated Sheets

- Monel K500 Perforated Sheets

- ASME SB127 400 Monel Perforated Sheets

- Monel K-500 Perforated Sheets

- Monel Alloy 400 Perforated Sheet

- Monel Alloy K500 Hot Rolled Perforated Sheets

- Monel 2.4360 Perforated Sheet

- Monel 2.4375 Perforated Sheets

Shim Sheets

- Monel® Alloy 400 Shim Sheets

- Monel Alloy 2.4360 Cold Rolled Shim Sheets

- Monel 400 CR Shim Sheets

- Monel 2.4375 Shim Sheet

- Alloy 400 Hot Rolled Shim Sheets

- Monel N04400 HR Shim Sheets

- ASTM B127 Monel 400 Shim Sheet

- Monel 2.4375 Shim Sheets

- Monel Alloy K500 Shim Sheet

- K-500 Monel Shim Sheets

- Monel N04400 Shim Sheets

- ASME SB127 Monel K500 Monel Shim Sheets

- Monel UNS N05500 Shim Sheet

- Monel K500 Shim Sheets

Chemical Composition of Monel 400 / K500 Sheets

| Grades | C | Mn | Si | S | Cu | Fe | Ni |

| 400 | 0.30 max | 2.00 max | 0.50 max | 0.024 max | 28.00 – 34.00 | 2.50 max | 63.00 min |

| K500 | 0.30 max | 2.00 max | 0.50 max | 0.024 max | 28.00 – 34.00 | 2.50 max | 63.00 min |

Mechanical Properties of Monel 400 / K500 Plates

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.8 g/cm3 | 1350 °C (2460 °F) | Psi – 80,000 , MPa – 550 | Psi – 35,000 , MPa – 240 | 40 % |

Other Types of 400 / K500 Monel Coils Ready Stock

- Monel N04400 Sheets Dealer

- Monel N05500 Sheets & Plates, coils

- Monel Alloy 400 Chequered Plate Dealer in India

- 400 Monel Sheets, Plate, Coils

- Grade K500 Monel CR Sheets

- Monel 400 Sheets & Plates, Coils Supplier in Mumbai

- 400 Monel Alloy Rolls

- ASTM B127 K500 Monel Plate

- ASTM B127 400 Coils at Best Price in India

- Alloy 400 Slit Coils Wholesaler

- Monel K500 Plate Supplier in India

- Monel 2.4360 Sheets Exporter

- Alloy 400 Sheets

- Monel UNS N04400 Blank Supplier

- ASTM B127 Monel K500 Plate

- Monel 400 CR Sheets & Plates and Coils Supplier in India

- Monel Alloy K-500 Plate Manufacturer

- Monel 400 Shim Sheet Supplier

- Monel Alloy K500 Perforated Sheet Stockist

- Monel 400 Plates Manufacturer

- Monel Alloy N05500 Sheets

- 400 Monel Shims

- K500 Monel Alloy Plasma Cutting Plate

- Monel® Alloy 400 Sheets

- Monel Alloy K500 Coils Stockists

- Monel Alloy 400 Strips Supplier

- Monel 2.4375 Plates

- 2.4360 Monel Plates

- Grade K500 Monel Blank Sheet

- ASME SB127 Monel 400 Plate

- Monel Alloy K500 Plate

- Monel 400 HR Sheets Supplier

- Monel Alloy 2.4375 Foils Exporter

- Alloy K500 Rings

ASME SB127 400 / K500 Monel Sheets Applications and Uses

Searches Related to Monel 400 / K500 Plates

Export Destinations of Monel 400 / K500 Coils

Countries where we export Monel 400 / K500 Sheets

Libya, Portugal, Ukraine, Australia, Italy, Ghana, South Africa, Ecuador, Hungary, Brazil, RuMonel ia, Nigeria, Mongolia, Qatar, Chile, Denmark, Japan, Bhutan, Azerbaijan, Poland, Sri Lanka, Philippines, Netherlands, Peru, Turkey, Switzerland, Pakistan, Bangladesh, Finland, Yemen, Trinidad & Tobago, Argentina, Belarus, Costa Rica, Malaysia, Kuwait, Indonesia, Mexico, Nigeria, United Arab Emirates, Belgium, Slovakia, Taiwan, Jordan, Chile, Austria, Oman, Vietnam, Iran, New Zealand, Canada, Iraq, United States, Saudi Arabia, Lithuania, United Kingdom, Gabon, Greece, Iran, South Korea, Venezuela, Estonia, Bahrain, France, Bulgaria, Serbia, Poland, Norway, Morocco, China, Bolivia, Kazakhstan, Algeria , Spain, Afghanistan, Hong Kong, Mexico, Angola, Egypt, Israel, Sweden, Croatia, Tunisia, Thailand, Romania, Kenya, Czech Republic, Lebanon, Singapore, Colombia.