Inconel 600 Fasteners Supplier

Table Of Content

- What is Inconel 600 Fasteners

- Specification of Inconel 600 Fasteners

- Inconel 600 Fasteners Equivalent Grades

- ASTM B166 Inconel 600 Fasteners Types

- Chemical Composition of Inconel 600 Fasteners

- Mechanical Properties of Inconel 600 Fasteners

- Other Types of Inconel 600 Fasteners Ready Stock

- ASME SB166 Inconel 600 Fasteners Applications

- Searches Related to Inconel 600 Fasteners

- Export Destinations for Inconel 600 Fasteners

ASME SB166 600 Inconel Alloy Fasteners, Inconel 600 Eye Bolt Manufacturers In India, inconel 600 suppliers, alloy 600 distributor, inconel 600 bolts, inconel 600 fasteners, inconel 600 gasket coil, inconel 600 stud bolts, Nickel Alloy 600 Fasteners, ASTM B166 Alloy 600 Nuts, Inconel Alloy 2.4816 Fasteners, 600 Inconel Nuts and Bolts, Inconel Alloy 600 Fastener Price, UNS N06600 Fasteners, Alloy 600 Fasteners, Inconel® Alloy 600 Fasteners, Inconel 600 Fasteners Supplier in Mumbai, India.

Inconel 600 Fasteners. Inconel alloy is a superalloy that contains nickel and chromium. This alloy is perfect for extreme environments subjected to high pressure and heat. At high temperatures, this alloy is stronger than stainless steel. Inconel 600 Fasteners provide excellent resistance to highly corrosive media. Inconel 600 has good resistance properties than other alloys in oxidizing conditions. This Inconel 600 contains nickel and is highly resistant to reducing conditions. Fasteners made of Inconel 600 facilitate the production of a passivating oxide layer, which protects the fasteners from oxidative corrosion.

Inconel 600 Fasteners have immunity to chlorine ion stress-related corrosion cracking. These fasteners are also resistant to formic acid, acetic acid, and stearic acid. The chromium content of Inconel 600 shows resistance to corrosion, opposite to sulfur-containing compounds.

Inconel 625 Nuts is a type of fastener which are non-magnetic and has good formability. Inconel 625 Screws can retain their toughness at high temperatures. Nickel, chromium, iron, and other substances try to compensate for Inconel 600. It is a reliable method for fortifying the alloy needed for increased temperature stability, and it also offers enough corrosion resistance. These fasteners function well in both moderate and high temperatures up to 2000 degrees Fahrenheit. These fasteners are produced using industry-standard machinery in both cold and hot forming processes. Inconel grade is hot work at temperatures between 1600 and 2250 degrees Fahrenheit. The ductility of this alloy increases with temperature.

Nickel Alloy 600 Heavy Hex Nuts, Inconel Alloy 600 Self Drilling Screw, Inconel Alloy 600 Stud Bolts, 600 Inconel Washers, inconel 600 stud bolts manufacturer, alloy 600 fasteners, 600 Inconel Alloy Fasteners, Alloy 600 Fasteners, Inconel Alloy 600 Screw, Inconel Alloy 600 Anchor Fasteners, Inconel 600 Bolts, Nickel Alloy 600 Threaded Rod, 600 Inconel Alloy Fasteners Stockist, Inconel 600 Hex Bolts, Inconel® 600 Dome Washer, Inconel 600 Nuts, Inconel Alloy 600 Industrial Fasteners Manufacturer in Mumbai, India.

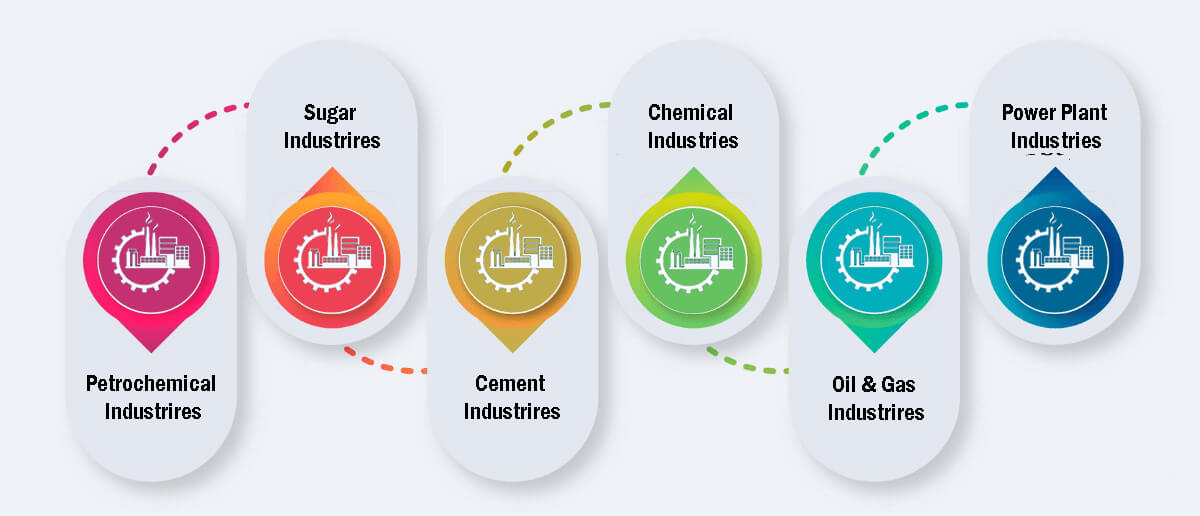

Inconel 625 Fasteners are famous for opposing steam, air, carbon dioxide, and mixtures of steam. Because of its high resistance to pure water, fasteners made from the alloy Inconel 600 can be used in primary and secondary circuits of pressurized nuclear reactors. At room temperature and high temperature, no attack will happen on the fasteners due to the addition of dry gases like chloride and hydrochloride. These fasteners are a combination of high mechanical properties like good workability, strength, and weldability is also good. Those fasteners are used in different types of applications, including in power plants, the defense industry, the fabrication industry, and general-purpose applications. In the construction industry and water supply systems, these fasteners are also used.

Specification of Inconel 600 Fasteners

| Standard | ASTM B166 / ASME SB 166 |

| Bolt / Screw Size | M3 – M56 | 3/6″ to 2″ | Custom Sizes |

| Nuts Size | M3 – M56 | 3/6″ to 2″ | Custom Sizes |

| Washers Size | M3 – M56 | 3/6″ to 2″ | Custom Sizes |

| Machine Screws Size | M1.6 – M12 |

| Self Tapping Screw Size | No.2 – No. 14 |

| Length | 3 mm to 200 mm |

| Studs, Bolts, Threads | UNF, BSW, BSF, METRIC, UNC, or as required |

| Threads Configuration | ASME B1.1 2A/3A – 2B/3B Inch Unified Threads and B1.13M 6h-6G Metric Coarse Threads |

| Certification | Dual Certified As per ASTM & ASME Codes |

| Dimensions | DIN 931, 933, 934, 7991, 976, 125, ASME B18.2.1, B18.3 |

| Threads | Unless otherwise specified, the threads shall be rolled or cut and tapped horizontally or vertically |

| Test Certificate of Bolting | as per EN 10204 / 3.1 Manufacturer Test Certificate |

Inconel 600 Fasteners Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Inconel 600 | 2.4816 | N06600 | NCF 600 | NA 13 | МНЖМц 28-2,5-1,5 | NC15FE11M | NiCr15Fe |

ASTM B166 Inconel 600 Fasteners Types

Nuts

- Inconel 600 Nyloc Nuts

- Inconel 600 Nuts

- ASME SB 166 600 Inconel Nuts

- ASTM B166 Inconel 600 Hex Nuts

- Inconel® 600 Heavy Hex Nut

- Inconel 600 Coupling Nut

- Inconel 600 Hex Jam Nuts

- 600 Inconel Slotted Nut

- 600 Inconel Alloy Machine Hex Nuts

- Alloy 600 Square Nuts

- UNS N06600 Wing Nuts

- Nickel Alloy 600 Cap Nuts

- Inconel Alloy 600 Dome Nuts

- Inconel 2.4816 Lock Nut

Bolts

- ASTM B166 Inconel 600 Hex Bolts

- Nickel Alloy 600 Machine Bolts

- Inconel Alloy 600 Hexagon Bolts

- Alloy 600 Flange Bolts

- Inconel 2.4816 Carriage Bolts

- UNS N06600 J Bolts

- Inconel® Alloy 600 Long Bolts

- 600 Inconel Metric Bolts

- Inconel 600 Heavy Hex Bolt

- Alloy 600 Button Head Bolt

- Inconel 600 Bolts

- 600 Inconel Alloy Foundation Bolts

- ASME SB 166 600 Inconel Bolts

- Inconel 600 Eye Bolts

Screw

- Alloy 600 Phillips Head Screw

- Inconel® Alloy 600 Machine Screw

- Inconel 600 Metric Set Screw

- Inconel 600 Screw

- 600 Inconel Alloy Thread Rolling Screw

- ASTM B166 Inconel 600 Allen Cap Screw

- Inconel Alloy 2.4816 Roofing Screw

- Inconel 600 Wood Screw

- ASME SB 166 600 Inconel Socket Head Cap Screw

- Nickel Alloy 600 Hex Head Screw

- Inconel 600 Self Tapping Screw

- UNS N06600 Eye Screw

- Alloy 600 Self Drilling Screw

Washers

- 600 Inconel Split Washer

- Inconel Alloy 600 Split Washers

- Inconel 2.4816 High Tensile Washer

- Inconel 600 Plain Washers

- Alloy 600 Countersunk Washer

- Nickel Alloy 600 Hex Washer

- ASME SB 166 600 Inconel Locking Washer

- Inconel 600 Star Washer

- ASTM B166 Inconel 600 Spring Washers

- Inconel 600 Fender Washer

- 600 Inconel Alloy Square Washer

- Inconel 600 Flat Washer

- UNS N06600 Ogee Washers

- Inconel® 600 Washers

Stud Bolts

- Inconel 600 Heavy Stud Bolts

- Inconel 600 Stud

- Nickel Alloy 600 Stud Bolt

- 600 Inconel Stud

- ASME SB 166 600 Inconel Stud Bolt

- Inconel 600 Tie Rods

- Inconel® 600 Full Threaded Stud Bolts

- Inconel 600 Double Ended Studs

- ASTM B166 Inconel 600 Half Threaded Stud Bolt

- Alloy 2.4816 Tap End Stud Bolt

- Alloy 600 Stud Bolts

- UNS N06600 Threaded Rod

- Inconel Alloy 600 Single End Stud Bolts

- 600 Inconel Alloy Partial Threads Stud Bolt

Anchor Bolts

- 600 Inconel Anchor Bolts

- Inconel Alloy 600 Wedge Anchor Bolt

- Inconel Alloy 600 Anchor Bolts

- Nickel Alloy 600 J Anchor Bolts

- 600 Inconel Alloy Self Tapping Anchor

- Alloy 600 Sleeve Anchor Bolts

- UNS N06600 Anchor Bolts

- ASTM B166 Inconel 600 Anchor Bolts

- Inconel® Alloy 600 Anchor Bolts

- Alloy 600 Concrete Anchor

- ASME SB 166 600 Inconel Anchor Bolts

- Inconel 600 Anchor Bolt

- Inconel 2.4816 Anchor Bolts

- Inconel 600 Anchor Bolts

Chemical Composition of Inconel 600 Fasteners

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel 600 | 0.15 max | 1.00 max | 0.50 max | 0.015max | 0.50 max | 6.00 – 10.00 | 72.00 min | 14.00 – 17.00 |

Mechanical Properties of Inconel 600 Fasteners

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Inconel 600 | 8.47 g/cm3 | 1413 °C (2580 °F) | Psi – 95,000 , MPa – 655 | Psi – 45,000 , MPa – 310 | 40 % |

Other Types of Inconel 600 Fasteners Ready Stock

- ASME SB166 Inconel 600 Particle Board Screw

- 600 Inconel Alloy Split / Lock Washer Dealer

- Alloy 600 Flange Lock Nut Wholesaler

- Inconel 600 T-Head Bolts

- Nickel Alloy 600 Hexagonal Washer Supplier in India

- ASTM B166 Inconel Alloy 600 Foundation Bolts

- Inconel Alloy 600 Hanger Bolts

- Alloy 600 Construction Screws Manufacturer

- Inconel 600 Hex Coupling Nut

- Inconel Alloy 600 Elevator Bolt

- 600 Inconel Hex Washers

- 600 Inconel Fender Washer

- Inconel 2.4816 Fasteners

- Inconel 600 Flat Washers

- Inconel 600 Carriage Bolt

- Inconel Alloy 600 Structural Bolts Stockist

- 600 Inconel Alloy Socket Cap Screw

- Inconel 600 Hex Head Bolt

- 600 Inconel Countersunk Washer Supplier

- Inconel UNS N06600 Fasteners Stockist

- Inconel 600 Tooth Lock Washer

- Austenitic Inconel 600 Machine Fasteners

- Alloy 600 Machine Bolts Manufacturer

- Inconel Alloy 600 Flange Bolt Supplier in Mumbai

- Inconel 600 Lag Fasteners Supplier in India

- Inconel 600 Dock Washer

- UNS N06600 Concrete Screw Supplier

- Inconel 600 Bolted Joints Stockists

- 600 Inconel Alloy Threaded Rod

- Inconel Alloy 600 Hex Head Fasteners

- Inconel® Alloy 600 Mushroom Head Square Neck Bolts

- Inconel 2.4816 Self Locking Nuts

- ASME SB166 600 Inconel Alloy Double Ended Stud

- ASME SB166 Inconel 600 Coupling Nut

- Inconel Alloy 2.4816 Thread Cutting Screw Exporter

- Nickel Alloy 600 Hex Set Screw Exporter

- Nickel Alloy 600 Allen Cap Screw Supplier

- Inconel 600 Thread Rolling Screw

- Inconel® Alloy 600 Hex Domed Cap Nuts Dealer in India

- ASTM B166 600 Wing Nuts at Best Price in India

ASME SB166 Inconel 600 Fasteners Applications