Hastelloy Flanges Supplier

Hastelloy Flanges, ANSI B16.5 Hastelloy Flanges, Hastelloy® Alloy Flanges, Hastelloy Alloy Flange, Hastelloy Pipe Flanges, Hastelloy Industrial Flanges, ASTM B564 Hastelloy Flange Supplier in Mumbai, India.

Due to their characteristics, these Hastelloy Flanges are extensively used in Process Piping, Heat Exchangers, Pickling Equipment, and many more. The manufacturers can produce these flanges with national and international quality standards. Hastelloy Flanges come in different sizes, specifications, standards, grades, diameters, and dimensions. These specifications depend on the application working flow, and they work on various aspects of the Hastelloy Flanges.

Hastelloy materials are typically Nickel and cobalt-based alloys that offer excellent corrosion, temperature, and wear-resistant; they are classified as moderate to complex when machining processes are done. Among numerous metallic materials, Hastelloy grades have the highest levels of corrosion resistance. While Nickel and molybdenum are alloying elements in the chemical characteristics of some of these categories, chromium is a more significant addition to the chemistry of the other grades. The Hastelloy Flanges Manufacturer has graded and produced these alloys under an application’s requirements.

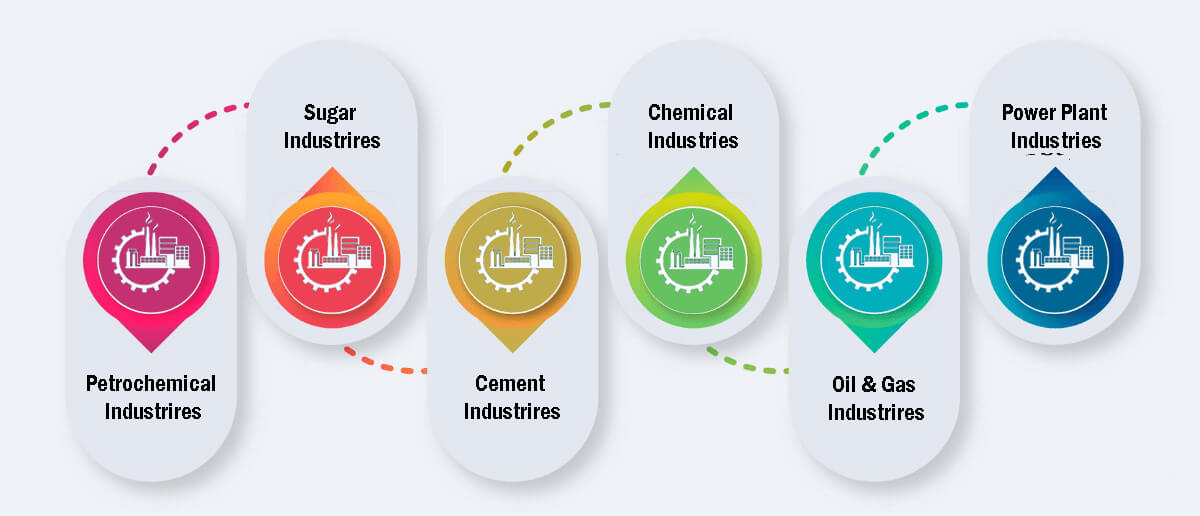

Besides, Hastelloy should be emphasized with these alloys to be processed easily using conventional production methods while manufacturing the Hastelloy Flanges. Moreover, these Hastelloy Flanges have excellent mechanical properties as they offer moderate strength, have high-density powers, are malleable, and come with a high surface finish. Hastelloy Flanges contain outstanding corrosion resistance in oxidizing and reducing media, making them well-matched for various corrosive solid applications. It has exceptional resistance to both sulfuric and hydrochloric acid. These flanges are usually used in chemical applications such as acid chlorides, solvents, formic and acetic acids, acetic anhydride, wet chlorine gas, hypochlorite, chlorine solutions, etc. It shows excellent mechanical properties at high temperatures. These flanges are also used in solar energy, oil and gas, and pharmaceutical industries.

Hastelloy® Alloy Forged Flanges, Hastelloy Raised Face Flanges, Hastelloy Alloy Weld Neck Flanges, Hastelloy Threaded Flanges Stockist, Hastelloy Alloy Spectacle Blind Flanges, Hastelloy Groove & Tongue Flanges, Hastelloy Alloy Ring Type Joint Flanges, ASME SB 564 Hastelloy Flanges, Hastelloy Blind Flanges, Hastelloy Alloy Socket weld Flanges, Hastelloy Slip On Flanges, Hastelloy Alloy Flat Face Flange, Hastelloy Flange Price, Hastelloy Plate Flanges Manufacturer in Mumbai, India.

This alloy also contains silicon, iron, phosphorus, chromium, manganese, sulfur, and carbon. Due to their high melting point, these flanges can withstand extremely high temperatures. Furthermore, the flanges have a high level of corrosion resistance and substantial tensile and yield strength. These flanges are frequently used in petrochemical and pharmaceutical industries, heat exchangers, and marine applications.

Standard Specification For Hastelloy Flanges

| Specifications | ASTM B564 / ASME SB564 |

| Flange size range | 1/2″ (15 NB) to 48″ (1200NB) DN10~DN5000 |

| Flanges Dimensions | ANSI/ ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Flanges Standard | ANSI Flanges, AWWA Flanges, ASME Flanges, BS 10 Table D Flanges, Table E Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flanges. |

| Pressure Class / Rating | Class 150 LBS, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Flange Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Large Male-Female (LMF), Flat Face (FF), Small Male-Female (SMF), Lap-Joint Face (LJF), Small Tongue, Large Tongue & Groove |

| Specialized manufacturer of | Weld Neck Ring Flanges (WNRF), Slip-On Ring Flanges (SORF), Blind Ring Flanges (BLRF), Socket Weld Ring Flanges (SWRF), Lap Joint Ring Flanges (LJRF), Ring Type Joint Flanges (RTJF), Large Diameter Flanges, Orifice Flanges |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

ASTM A564 Hastelloy Flanges Types

Slip on Flange

- ASME SB564 Hastelloy Alloy Slip on Flange

- Hastelloy Alloy Slip on Flanges

- Hastelloy® Alloy Raised Face Slip on Flange

- Hastelloy SORTJ Flange

- Hastelloy Alloy RFSO Flange

- Hastelloy Alloy Slip on Flanges

- Hastelloy SORF Flanges

- Hastelloy ASTM B564 Slip on Flange

- Hastelloy Alloy Slip on Flanges

- ANSI B16.5 Hastelloy® Alloy Slip on Flange

Weld Neck Flange

- Hastelloy® Alloy Weld Neck Flange

- Hastelloy Alloy Weld Neck Flange

- ASME SB564 Hastelloy Alloy Weld Neck Flange

- ANSI B16.5 Hastelloy Weld Neck Flange

- Hastelloy Weld Neck Flanges

- Hastelloy Weld Neck Flanges

- ASTM B564 Hastelloy Alloy Weld Neck Flange

- Hastelloy Alloy WNRTJ Flange

- Hastelloy® Alloy WNFF Flanges

- Hastelloy Alloy RFWN Flange

Blind Flange

- Hastelloy Alloy BLRTJ Flanges

- ASTM B564 Hastelloy Alloy Blind Flange

- Hastelloy Alloy Blind Flange

- ANSI B16.5 Hastelloy Blind Flange

- Hastelloy Alloy Blind Flanges

- Hastelloy Alloy BLFF Flange

- ASME SB564 Hastelloy Blind Flange

- Hastelloy® Alloy RFBL Flanges

Socket weld Flange

- ASME SB564 Hastelloy Socket weld Flange

- Hastelloy Socket weld Pipe Flange

- Hastelloy ASTM B564 Socket weld Flange

- ANSI B16.5 Hastelloy Socket weld Flange

- Hastelloy Alloy Socket weld Flanges

- Hastelloy® Alloy RFSW Flange

- Hastelloy® Alloy Socket weld Flanges

- Hastelloy® Alloy SWRTJ Flanges

- Hastelloy Alloy Socket weld Flanges

- Hastelloy Alloy SWRF Flanges

Ring Type Joint Flange

- Hastelloy Ring Type Joint Flanges

- Hastelloy RTJ Flanges

- Hastelloy Alloy Ring Type Joint Pipe Flange

- ANSI B16.5 Hastelloy Alloy Ring Type Joint Flange

- Hastelloy Alloy Ring Joint Flanges

- Hastelloy® Alloy Ring Type Joint Flange

- ASTM B564 Hastelloy Ring Type Joint Flange

- ASME SB564 Hastelloy Ring Type Joint Flange

- Hastelloy® Alloy Ring Type Joint Flanges

- Hastelloy Ring Type Joint Flange

Spectacle Blind Flange

- Hastelloy Alloy Spectacle Blind Flanges

- ASTM B564 Hastelloy Spectacle Blind Flange

- ANSI B16.5 Hastelloy Alloy Spectacle Blind Flange

- ASME SB564 Hastelloy Alloy Spectacle Blind Flange

- Hastelloy® Alloy Spectacle Blind Flanges

- Hastelloy Alloy Spectacle Blind Pipe Flange

- Hastelloy Spectacle Blind Flanges

Other Types of Hastelloy Flanges Ready Stock

- Hastelloy Alloy RTJF Flanges

- Hastelloy Socket weld Flanges Dealer in India

- Hastelloy Nipo Flanges

- Hastelloy Ring Type Joint Flanges

- Hastelloy Loose Flanges Manufacturer

- Hastelloy Raised Face Flange

- Hastelloy Alloy Weld Neck Flanges

- Hastelloy Alloy Blind Flanges Stockists

- Hastelloy Alloy Flanges Dimensions

- Hastelloy Alloy 10K Flanges

- ASTM B564 Hastelloy Tongue & Groove Flanges

- Hastelloy Alloy Male & Female Flanges

- Hastelloy Alloy Lap Joint Flanges Supplier

- Hastelloy Alloy Long Weld Neck Flanges

- Hastelloy Alloy Raised Face Flanges

- Hastelloy Alloy Alloy Slip on Flanges

- B564 Hastelloy Flanges Facing Type & Finish

- Hastelloy® Alloy Forged Flanges Wholesaler

- ASME SB564 Hastelloy Flat Face Flange

- ASME SB564 Hastelloy Spectacle Blind Flanges

- ASTM B564 Hastelloy Threaded Flanges

- Hastelloy Alloy Weldo Flanges

- Hastelloy Forging Facing Flanges Dealer

- Hastelloy Alloy Hastelloy SORF Flanges Exporter

- Hastelloy Nipoflange

- Hastelloy Alloy Flanges

- Hastelloy Reducing Flanges

- ASTM B564 Hastelloy® Alloy Screwed Flanges

- Hastelloy Blind Flange

- ASTM B564 Expander Flanges at Best Price in India

- ASTM B564 Hastelloy Flanges Facing Type & Finish

- Hastelloy Orifice Flange

- Hastelloy® Alloy High Hub Blinds Flanges

- Hastelloy® Alloy Puddle Flanges Exporter

- ASME SB564 Hastelloy Expander Flanges

- Hastelloy Alloy Plate Flange Supplier in Mumbai

- Hastelloy Flat Flange Supplier in India

- Hastelloy Alloy Reducing Flanges Supplier

- ASME B16.5 Hastelloy Flanges

- Hastelloy Spades Ring Spacers Flanges

- Hastelloy Alloy BLRF Flange Manufacturer

- Hastelloy Alloy BLRF Flanges Supplier

- Hastelloy Long Weld Neck Flanges Stockist

- Hastelloy Flanges Supplier in India

- Hastelloy Socket Welding Flange

- Hastelloy Alloy Spades Ring Spacers Flanges

- ANSI B16.5 Hastelloy Pipe Flange

- Hastelloy Plate Flanges

- Hastelloy Long Welding Neck Flange

- Hastelloy DIN Flanges

ASME SB564 Hastelloy Flanges Applications