Alloy 28 Fittings Supplier

Table Of Content

- What is Alloy 28 Fittings

- Standard Specification For Alloy 28 Fittings

- 28 Alloy Fittings Equivalent Grades

- ASTM B366, B564 Alloy 28 Fittings Types

- Chemical Composition of Alloy 28 Fittings

- Mechanical Properties of Alloy 28 Fittings

- Other Types of Alloy 28 Fittings Ready Stock

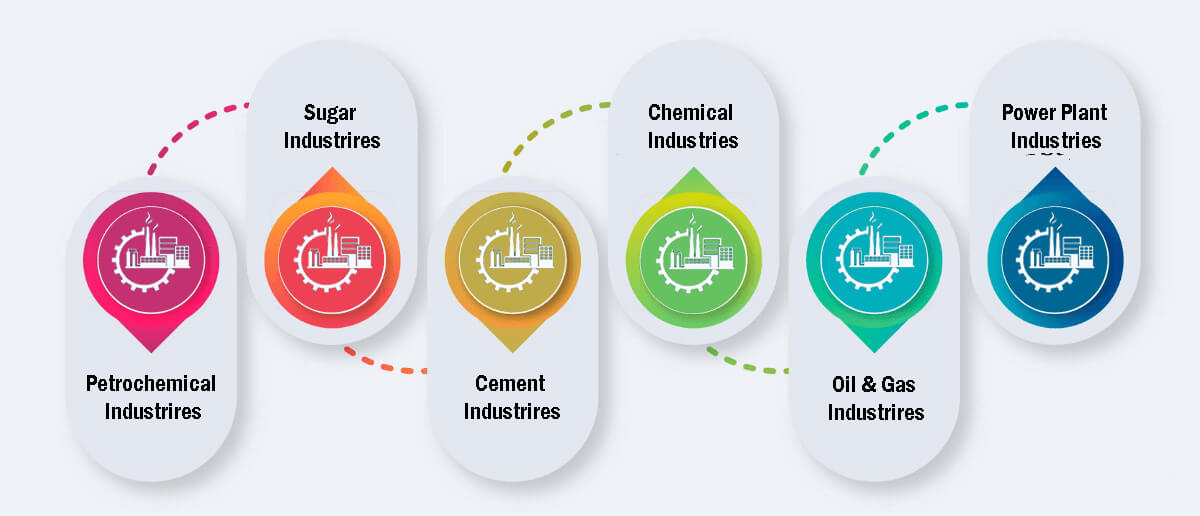

- ASME B16.9 / B16.11 Alloy 28 Fittings Applications

- Searches Related to Alloy 28 Fittings

- Export Destinations for Alloy 28 Fittings

ASTM B564 Alloy 28 Threaded / Screwed Fittings, Alloy 28 Buttweld Fittings, Alloy ASTM B366 28 Pipe Fittings, ANSI B16.9 / B16.11 Alloy 28, Alloy 28 Fittings, Alloy 28 1D, 1.5D, 2D, 3D, 5D, 10D Bends, UNS N08028 Fittings, Alloy 28 Seamless Pipe Fittings, Alloy 28 High Pressure Forged Fittings, Alloy 1.4563 Fittings, Alloy 28 Forged Fittings, UNS N08028 Pipe Fittings, Alloy 1.4563 Socket Weld Fittings, Alloy 28 Fittings Supplier in Mumbai, India.

Alloy 28 Fittings are designed and developed by Navgraha Steel & Engg Company. These Fittings are of high quality. By using authentic stainless steel as raw material, we produce the versatile product. We customize products to withstand severe corrosive conditions well. The raw materials we use are resistant to strong acids and other substances. Our company purchases the high-grade raw material from our renowned suppliers. Alloy 28 Fittings are indistinguishable except for the superior level of carbon in alloy and the addition of up titanium and aluminium. These elements provide good resistance against sulphuric and phosphoric acids as well as improved resistance to localized corrosion, including pitting and crevice corrosion, as well as stress corrosion.

We start the manufacturing only after testing raw material for various physical, chemical, and mechanical properties. When testing raw materials, we also check the same quality parameters of the final product. In addition to this, we do cross verify the thermal properties of Alloy 28 Fittings. Our team works in the most diverse environments and brings the outcome of international quality standards. These Alloy 28 Fittings are used for evaporator tubes, piping, and heat exchangers. In addition, the product can also work well in the oil and gas industry, where corrosion and leakage may occur. Here, the product is exposed to high temperatures and processed to confirm its ductility and durability.

Alloy 28 Pipe Cap, Alloy 28 Socket Weld Pipe Fittings, Alloy 28 Unions, Alloy 28 Buttweld Elbow, Alloy 28 Pipe Nipple, Alloy 28 Long Stub Ends, Alloy 28 Threaded Plug, Alloy 28 Reducers, Alloy 28 Fittings price, Alloy 28 1D, 1.5D, 2D, 3D, 5D, 10D Elbow, Alloy 28 Couplings, Alloy 28 Reducing Elbow, Grade Alloy 28 Pipe Cross, Alloy 28 Forged Tee Stockist, Alloy 28 Short Stub End, Alloy 28 Industrial Fittings Manufacturer in Mumbai, India.

We at Navgraha Steel & Engg Company have a well established manufacturing unit along with a well equipped unit to perform various tests. The company can offer a comprehensive range of Alloy 28 Fittings along with proper documentation and reporting. Our machinists use different grades of raw materials to manufacture products of various sizes and specifications to meet customer needs. We are involved in the production of various ranges of Alloy 28 Fittings. Our company can provide a product which is customized shapes or a variety of sizes and shapes to meet the needs of immediate use. We guarantee the quality of our products. We use suitable materials for packaging so that our packing makes sure that there is no damage during storage and transportation.

Specification of Alloy 28 Fittings

| Specifications | ASTM B564 / ASME SA366, ASTM B564 & ASME SA366 |

| Forged Fittings Standards | ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799 |

| Buttweld Fittings Dimensions | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43 |

| Buttweld Fittings Size | 1/8” NB TO 48” NB. (Seamless & 100% X-Ray Welded, Fabricated) |

| Forged Fittings Size | 1/8” NB to 4” NB (Socketweld & Screwed-Threaded) |

| Buttweld Fittings Type | Seamless / Welded / Fabricated |

| Forged Fittings Type | Socketweld Fittings, Screwed-Threaded Fittings |

| Forged Fittings Class | 2000 LBS, 3000 LBS, 6000 LBS, 9000 LBS |

| Buttweld Fittings Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom |

| Buttweld Fittings Thickness | Sch 5s, Sch 10s, Sch 40s, Sch 80s, Sch 160s, Sch XXS |

Alloy 28 Fittings Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | EN | AFNOR |

| Alloy 28 | 1.4563 | N08028 | X1NiCrMo31-27-4 | Z1NCDU31-27-03 |

Products Range of Alloy 28 Fittings

Elbow

- Alloy ASTM B564 28 Forged Elbow

- Alloy 28 Elbow

- ASME SB366 Alloy 28 Pipe Elbow

- Alloy 28 Screwed / Threaded Elbow

- Alloy 28 Socket weld Elbow

- UNS N08028 Buttweld 10D Elbow

- Alloy 28 Welded Pipe Elbow

- UNS N08028 90 Deg. LR Elbow

- Alloy 28 Seamless Elbow

- ANSI B16.9 Alloy 28 Elbow

- Alloy 28 1.5D Elbow Suppliers

- Alloy 1.4563 Reducing Elbow

- Alloy 28 2D Elbow

- Alloy 1.4563 45 Degree Forged Elbow

- Alloy 1.4563 Short Radius Elbow

Tee

- Alloy 28 Seamless Tee

- Alloy 1.4563 Unequal Tee

- Alloy 28 Welded Pipe Tee

- Alloy 1.4563 Reducing Tee

- Alloy 28 Tee Suppliers

- Alloy 28 Tee Exporters

- ANSI B16.9 Alloy 28 Tee

- ASTM B564 Alloy 28 Forged Tee

- Alloy 28 Socket weld Tee

- UNS N08028 Buttweld Tee

- ASME SB366 Alloy 28 Pipe Tee

- Alloy 28 Screwed / Threaded Tee

- UNS N08028 Equal Tee

- Alloy 1.4563 Forged Tee

Cross

- Alloy 1.4563 Reducing Cross

- Alloy 28 Cross

- ANSI B16.9 Alloy 28 Cross

- Alloy 28 Cross Suppliers

- ASTM B564 Alloy 28 Forged Cross

- UNS N08028 Buttweld Cross

- Alloy 28 Socket weld Cross

- Alloy 1.4563 Forged Cross

- Alloy 28 Screwed / Threaded Cross

- UNS N08028 Equal Cross

- Alloy 28 Seamless Cross

- Alloy 28 Welded Pipe Cross

- ASME SB366 Alloy 28 Pipe Cross

- Alloy 1.4563 Unequal Cross

Pipe Cap

- Alloy 28 Pipe Cap

- UNS N08028 Butt weld Cap

- ASTM B564 28 Forged Pipe Cap

- UNS N08028 End Pipe Cap

- ANSI B16.9 Alloy 28 Pipe Cap

- Alloy 28 Pipe Cap Exporters

- Alloy 1.4563 Pipe End Cap

- Alloy 1.4563 Forged Pipe Cap

- Alloy 28 Screwed / Threaded Pipe Cap

- Alloy 28 Socket weld Pipe Cap

- Alloy 1.4563 Buttweld End Cap

- Alloy 28 Seamless Pipe Cap

- ASME SB366 Alloy 28 Pipe Cap

Reducers

- Alloy 28 Reducers Suppliers

- ASTM B366 28 Pipe Reducers

- Alloy 1.4563 Concentric Reducer

- ASME SB366 Alloy 28 Reducers

- UNS N08028 Butt weld Reducers

- Alloy 1.4563 Eccentric Reducers

- ANSI B16.9 Alloy 28 Reducers

- Alloy 28 Reducers Suppliers

- Alloy 1.4563 Buttweld Reducer

- UNS N08028 Seamless Reducers

- Alloy 28 Buttweld Pipe Reducer

- Alloy 28 Reducers Exporters

Couplings

- Alloy 1.4563 Threaded Coupling

- ANSI B16.11 Alloy 28 Couplings

- ASME SB564 Alloy 28 Couplings

- Alloy 28 Couplings Suppliers

- UNS N08028 Screwed Couplings

- Alloy 28 Couplings Exporters

- Alloy 28 Socketweld Couplings

- UNS N08028 Forged Couplings

- ASTM B564 28 Pipe Couplings

- Alloy 1.4563 Full Coupling

- Alloy 1.4563 Half Couplings

ASTM B564 / B366 Alloy 28 Fittings Chemical Composition

| Grade | C | Si | Mn | P | S | Cr | Ni | Mo | Cu |

| Alloy 28 | 0.020 max | 0.6 max | 2.0 max | 0.025 max | 0.010 max | 27.00 | 31 | 3.5 | 1.0 |

Alloy 28 Fittings Mechanical Properties

| Element | Tensile Strength | Yield Strength (0.2%Offset) | Elongation | Hardness |

| Alloy 28 | 500-750 | 220 | 35 % | 230 |

Ready Stock of Alloy 28 Fittings

- Alloy 28 90 Deg Buttweld Elbow

- Alloy 28 Fittings Supplier in India

- Alloy 28 Seamless Fittings Supplier in Mumbai

- Alloy 28 Forged Fittings Supplier

- Alloy 28 5D Bends Dealer

- Alloy 28 BSP Threaded Fittings

- B564 Alloy 28 Barrel Nipple

- ANSI B16.9 Alloy 28 Pipe Fittings

- Alloy 1.4563 Forged Fittings Exporter

- Alloy 28 1D Elbow

- Alloy 28 NPT Threaded Fittings

- ASTM B366 28 Fittings at Best Price in India

- ASME SB564 Alloy 28 Forged Pipe Fittings

- Alloy 28 Socketweld Pipe Fittings

- Alloy 28 Round Head Plugs

- Grade Alloy 28 Pipe Fittings

- ASME SB366 Alloy 28 Butt weld Stub Ends

- Alloy 28 Hex Head Bushings

- 1.4563 Alloy Socket Weld Fittings

- Alloy 28 Fittings Exporters

- ASME SB564 Alloy 28 Threaded Fittings

- ASME B16.11 Alloy 45 deg. Elbow

- Alloy 28 Square Head Plugs

- Alloy 28 10D Elbow

- Alloy 28 Long Radius Elbow

- Alloy 28 Fittings Manufacturer

- Alloy 28 U Bends

- UNS N08028 Two Joint Fittings Supplier

- Alloy 1.4563 1.5D Elbow Exporter

- Alloy 28 Forged Hex Head Plug

- Alloy 28 Street Elbow Supplier

- Alloy 28 LR Buttweld Elbow

- Alloy 1.4563 Buttweld Fittings Dimensions

- Alloy 28 3D Bends Supplier in India

- Alloy 28 Fittings Dealer in India

- Grade Alloy 28 Buttweld Pipe Fittings

- Alloy 28 Socket Weld Fittings

- Alloy 28 2D, 3D, 5D Pipe Elbow

- Alloy 28 Buttweld Fittings Suppliers

- Alloy 28 Forged Fittings Stockist

- Alloy 28 Fittings Wholesaler

- ASTM B564 Alloy 28 Screwed Fittings

- Alloy 28 Buttweld Fittings Manufacturer

- Alloy 28 Fittings Stockists

- Alloy 28 Socket Weld Reducer Insert

- ASTM B366 Alloy 28 Welded Pipe Fittings

- ASTM B366 28 LR Buttweld Elbow

ASME SA564, B366 Alloy 28 Fittings Applications and Uses