Inconel 625 LCF Sheets / Plates Supplier

Table Of Content

- What is Inconel 625 LCF Sheets

- Standard Specification For Inconel 625 LCF Plates

- 625 LCF Inconel Sheets & Plates Equivalent Grades

- ASTM B443 Inconel 625 LCF Sheets Types

- Chemical Composition of Inconel 625 LCF Plates

- Mechanical Properties of Inconel 625 LCF Sheets & Plates

- Other Types of 625 LCF Inconel Sheets Ready Stock

- ASME SB443 625 LCF Inconel Plates Applications

- Searches Related to Inconel 625 LCF Sheets & Plates

- Export Destinations for Inconel 625 LCF Sheets

ASME SB443 Grade 1 Plates, Inconel 625 Plates and Sheets Cut to Size, Inconel ® Alloy 625 LCF Sheets, 625 LCF Inconel Alloy Plates, Inconel 2.4856 Plate, UNS N06625 Sheets, Inconel 2.4856 Sheets, ASTM B443 Inconel Alloy 625 LCF Sheets, ASME SB443 Inconel 625 LCF Plates, AMS 5879E Sheet, Inconel 625 Sheets & Plates, Inconel 625 LCF Sheet, Inconel 625 LCF Plate Price, Alloy 625 Sheets, Inconel 625 LCF Sheets & Plates Supplier in Mumbai, India.

Inconel 625 is a high-performance nickel-chromium-molybdenum alloy renowned for its excellent corrosion resistance and high-temperature strength. In sheet form, Inconel 625 finds extensive use in various industrial applications where these properties are crucial.

High-Temperature Strength: Inconel 625 maintains its strength and oxidation resistance at elevated temperatures, making it suitable for applications in extreme conditions such as heat exchangers, furnace hardware, and gas turbine components. Its high-temperature strength is crucial in environments where conventional stainless steel would fail.

Applications: Inconel 625 sheets are widely used in various industries:

Aerospace: Inconel 625 is utilized in aircraft components, such as engine exhaust systems and thrust-reverser systems, where high-temperature strength and corrosion resistance are critical.

Chemical Processing: The alloy is employed in chemical processing plants for components like reaction vessels, distillation columns, and heat exchangers due to its corrosion resistance in aggressive chemical environments.

Marine Engineering: Inconel 625 is favored for marine applications, including seawater piping systems and offshore structures, where resistance to corrosion in saltwater is essential.

Inconel Alloy 625 LCF Shim Sheets Stockist, Inconel 625 Sheets & Plates, ASME SB 443 Grade 1 Sheets, 625 LCF Inconel Plates, Inconel 625 LCF Industrial Sheets, AMS 5599J Sheet, Inconel 2.4856 Perforated Sheet, 625 LCF Inconel Chequered Plates, UNS N06625 Inconel CR Plates, Inconel 625 LCF Perforated Sheets, Inconel 625 LCF Sheets, ASTM B443 Inconel® Alloy 625 LCF Hot Rolled Sheets, Inconel 625 LCF Sheet Plates Manufacturer in Mumbai, India.

Power Generation: The alloy is used in power plants for components like steam generator tubing, turbine blades, and fasteners, benefiting from its high-temperature strength.

Oil and Gas: Inconel 625 is applied in oil and gas extraction and processing equipment, including wellhead components and downhole tools.

Fabrication and Availability: Inconel 625 sheets are typically available in various thicknesses and widths to accommodate different application requirements. The alloy can be easily fabricated using conventional techniques, including welding and machining, although its high strength and hardness may pose challenges.

Standard Specification For Inconel 625 LCF Plates

| Specifications | ASTM B443 , ASME SB443 |

| Dimensional specification | JIS, AISI, ASTM, GB, DIN, EN, etc |

| Width | 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc/td> |

| Thickness | 0.3 mm to 120 mm |

| Form | Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Perforated Sheet, Chequered Plate, Strip, Flats, Blank (Circle), Ring (Flange) etc. |

| Value Added Services | Cutting, Beveling, Polishing, Threading, Destructive, Non Destructive, Ultrasonic Testing |

| Outside Finish | Finish as per customer Requirements |

| Delivery Condition | Annealed and Pickled, Polished, Bright Annealed, Cold Drawn |

| Packing | Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests |

| Specials | Sizes and Specifications other than above can be on request |

625 LCF Inconel Sheets & Plates Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Inconel 625 LCF | 2.4856 | N06625 | NCF 625 | NA 21 | ХН75МБТЮ | NC22DNB4M | NiCr22Mo9Nb |

ASTM B443 Inconel 625 LCF Sheets Types

Sheets

- AMS 5879E Sheets

- UNS N06625 Shim Sheet

- Inconel Alloy 625 LCF Sheets

- Inconel N06625 Sheets

- ASTM B443 Inconel 625 lCF Sheet

- Inconel 2.4856 Cold Rolled Sheets

- Inconel Alloy 625 LCF Sheet

- Inconel Alloy 625 LCF Hot Rolled Sheets

- Inconel 625 LCF Sheets

- AMS 5599J Sheet

- Inconel ® Alloy 625 LCF CR Sheets

- ASME SB443 Inconel 625 LCF Sheets

- ASME SB 443 Grade 1 HR Sheets

- Inconel Alloy 625 LCF Sheets

Plates

- Inconel 2.4856 Cold Rolled Plates

- ASME SB443 625 LCF Inconel Plates

- Inconel Alloy 625 LCF Plate

- AMS 5599J Plates

- AMS 5879E Plates

- Inconel UNS N06625 Plate

- ASME SB 443 Grade 1 HR Plates

- Inconel Alloy 625 LCF Plates

- Inconel 625 LCF CR Plates

- Inconel Alloy 1.9859 Plate

- Inconel ® Alloy 625 LCF Hot Rolled Plates

- Inconel 625 LCF Plates

- Inconel Alloy 625 LCF Plates

- ASTM B443 Inconel 625 LCF Plate

Shim Sheets

- AMS 5599J Shim Sheets

- ASME SB 443 Grade 1 Shim Sheet

- Inconel Alloy 2.4856 Cold Rolled Shim Sheets

- Inconel N06625 HR Shim Sheets

- ASME SB443 Inconel 625 LCF Inconel Shim Sheets

- ASTM B443 Inconel 625 LCF Shim Sheet

- Inconel 625 LCF CR Shim Sheets

- Inconel Alloy 625 LCF Shim Sheet

- Inconel ® Alloy 625 LCF Shim Sheets

- 625 LCF Inconel Shim Sheets

- Inconel 625 LCF Shim Sheets

- AMS 5599J Shim Sheets

- Inconel 2.4856 Shim Sheet

- Inconel Alloy 625 LCF Hot Rolled Shim Sheets

Chemical Composition of Inconel 625 LCF Plates

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel 625 LCF | 0.10 max | 0.50 max | 0.50 max | 0.015 max | – | 5.0 max | 58.0 min | 20.0 – 23.0 |

Mechanical Properties of Inconel 625 LCF Sheets & Plates

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.4 g/cm3 | 1350 °C (2460 °F) | Psi – 1,35,000 , MPa – 930 | Psi – 75,000 , MPa – 517 | 42.5 % |

Other Types of 625 LCF Inconel Sheets Ready Stock

- ASTM B443 Inconel 625 LCF Plate

- Inconel Alloy 625 LCF Sheets Stockists

- Inconel Alloy 625 LCF Plate Manufacturer

- Inconel 2.4856 Sheets Exporter

- Inconel 625 LCF Shim Sheet Supplier

- Inconel 625 LCF Plates Manufacturer

- Inconel N06625 Sheets Dealer

- 625 LCF Inconel Shims

- Inconel Alloy 625 LCF Perforated Sheet Stockist

- Inconel 625 LCF CR Sheets Supplier in India

- AMS 5599J Sheet Exporter

- Inconel Alloy 625 LCF Chequered Plate Dealer in India

- ASME SB443 Inconel 625 LCF Plate

- Inconel 2.4856 Plates

- Inconel UNS N06625 Blank Supplier

- ASME SB 443 Grade 1 Sheet

- AMS 5599J Sheet Plate Wholesaler

- Inconel Alloy N06625 Sheets

- Inconel ® Alloy 625 LCF Sheets

- 625 LCF Inconel Plasma Cutting Plate

- Inconel 625 LCF Sheets & Plates Supplier in Mumbai

- Grade 625 LCF Inconel CR Sheets

- Inconel Alloy 625 LCF Plate

- 625 LCF Inconel Alloy Rolls

- Inconel 625 LCF HR Sheets Supplier

- Inconel 625 LCF Plate Supplier in India

- 2.4856 Inconel Plates

- ASTM B443 625 LCF Inconel Plate

- ASME SB443 Grade 1 Plates at Best Price in India

- 625 LCF Inconel Sheets & Plate

- Inconel N06625 Sheets & Plates

- Inconel Alloy 625 LCF Sheets

- Grade 625 LCF Inconel Blank Sheet

- AMS 5879E Plates Supplier

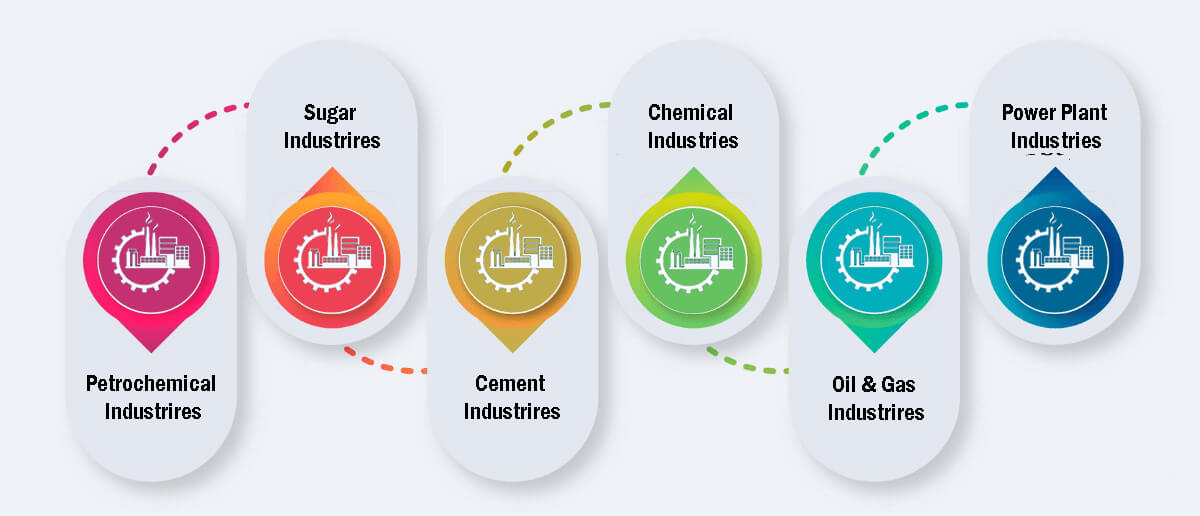

ASME SB443 625 LCF Inconel Plates Applications

Searches Related to Inconel 625 LCF Sheets & Plates

Export Destinations for Inconel 625 LCF Sheets

Countries where we export Inconel 625 LCF Sheets

Sweden, Bolivia, Bulgaria, United Kingdom, Ecuador, Ghana, Romania, Belgium, Bahrain, Trinidad & Tobago, Bangladesh, Switzerland, Greece, China, Singapore, Ukraine, Oman, Mongolia, Indonesia, Sri Lanka, Finland, Vietnam, Malaysia, France, Hungary, Pakistan, Czech Republic, Yemen, Morocco, Nigeria, Colombia, Bhutan, Netherlands, Costa Rica, Argentina, Hong Kong, South Africa, Algeria , Poland, United States, Iraq, Kenya, Egypt, RuInconel ia, South Korea, Gabon, Lithuania, Iran, Kazakhstan, Australia, Thailand, Venezuela, Nigeria, Angola, Kuwait, Poland, Italy, Belarus, Norway, Spain, Peru, Saudi Arabia, United Arab Emirates, Chile, Turkey, Brazil, Tunisia, Qatar, Philippines, Jordan, Iran, Azerbaijan, Canada, New Zealand, Libya, Lebanon, Afghanistan, Slovakia, Mexico, Serbia, Chile, Denmark, Israel, Japan, Croatia, Estonia, Portugal, Mexico, Taiwan, Austria.

Cities where we export Inconel 625 LCF Plates

Bhopal, Houston, Jaipur, Abu Dhabi, Ludhiana, Hanoi , Melbourne, Howrah, Visakhapatnam, Sharjah, Pune, Edmonton, Port-of-Spain, Courbevoie, Mumbai, Al Khobar, Coimbatore, Tehran, Kuwait City, Chiyoda, Baroda, Nashik, Muscat, Riyadh, Istanbul, Vadodara, Kanpur, Dallas, Kuala Lumpur, Santiago, Perth, Gimhae-si, Nagpur, Chandigarh, Hyderabad, Cairo, Sydney, Rajkot, Bogota, Ahvaz, Chennai, Jeddah, Petaling Jaya, Pimpri-Chinchwad, Gurgaon, Karachi, Granada, Lahore, Ranchi, Rio de Janeiro, Ernakulam, Madrid, Los Angeles, Navi Mumbai, Colombo, Jamshedpur, Bengaluru, La Victoria, Vung Tau, Surat, Geoje-si, New Delhi, Calgary, Noida, Algiers, Lagos, Milan, Ahmedabad, Busan, Brisbane, Dammam, Indore, Thiruvananthapuram, Kolkata, Ho Chi Minh City, Haryana, Thane, Dubai, Manama, New York, Jakarta, Bangkok, Ankara, Seoul, Montreal, Caracas, Doha, Secunderabad, Aberdeen, Toronto, Al Jubail, Faridabad, Atyrau, Ulsan.

PRODUCTS

- Inconel / Incoloy

- Hastelloy

- Monel

- Nickel

- Alloy 28

- Alloy 20

- Stainless Steel

- Duplex Steel

- Super Duplex Steel

- Alloy Steel

- Mild Steel / Carbon Steel

- Special Products

- Other Grades