In industries where high pressure, extreme temperatures, and structural integrity are critical, the choice of steel plate can significantly impact performance and safety. Two of the most commonly used types of steel plates are Boiler Quality Plates and Structural Steel Plates. Though both serve as essential building materials, they differ greatly in terms of mechanical properties, applications, and standards.

This blog will help you understand the major differences between Boiler Quality Plates and Structural Steel Plates, especially focusing on the features of IS 2041 R260 grade steel, and guide you in selecting the appropriate type for your industrial needs. We’ll also highlight where to find trusted boiler quality plates suppliers to ensure top-grade material for your project.

What are Boiler Quality Plates?

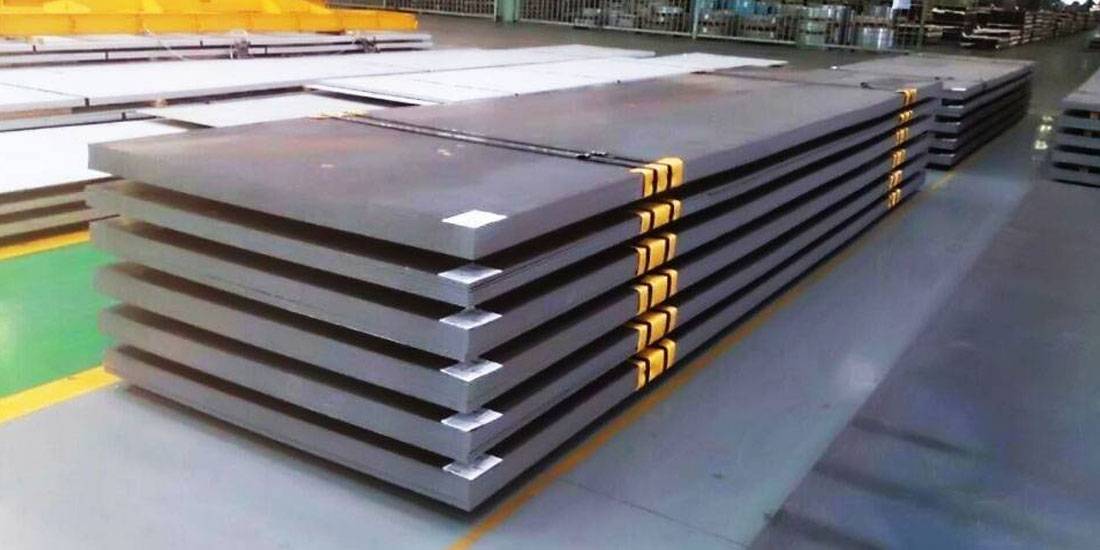

Boiler Quality Plates, often abbreviated as BQ plates, are specially designed to withstand high pressure and temperatures. They are primarily used in pressure vessels, boilers, heat exchangers, and similar high-stress environments.

Key Features:

- Excellent weldability

- High tensile strength

- Superior resistance to pressure and temperature

- Complies with specific standards like IS 2041 R260

The IS 2041 R260 standard defines the mechanical properties and chemical composition of boiler quality plates used in pressure-bearing applications. These plates are produced with strict quality control to meet safety requirements in heavy-duty industrial applications.

What is a Structural Steel Plate?

Structural Steel Plates are designed to bear structural loads. They are commonly used in construction, bridges, offshore platforms, and infrastructure projects. Unlike BQ plates, structural steel is more about providing support and load-bearing strength rather than resisting pressure or high temperature.

Key Features:

- High yield and tensile strength

These materials can withstand heavy loads and stress without deforming or breaking, making them ideal for structural applications.

- Good formability

They can be easily bent, shaped, or molded without cracking, which simplifies fabrication and welding processes.

- Standardized shapes for construction applications

Available in common sizes and profiles (like beams, angles, and channels), they meet industry norms for quick and easy use in building projects.

- Typically less expensive than BQ plates

These materials offer a cost-effective alternative to boiler quality (BQ) plates, especially for non-pressure-bearing structures.

While structural plates also come with certifications, the focus is usually on mechanical strength, not pressure resistance or temperature endurance.

Boiler Quality Plates vs. Structural Steel Plates: A Comparative Analysis

1. Application:

- Boiler Quality Plates: Primarily used in the construction of boilers, pressure vessels, and heat exchangers, which require materials capable of withstanding high temperatures and pressure.

- Structural Steel Plates: Used in buildings, bridges, and machinery structures, where strength and durability are important but not necessarily for handling extreme temperature or pressure conditions.

2. Temperature Resistance:

- Boiler Quality Plates: Designed to withstand high temperatures, often used in environments with extreme heat such as in boilers and pressure vessels.

- Structural Steel Plates: Suitable for ambient to slightly elevated temperatures, not intended for high-temperature environments like boiler quality plates.

3. Pressure Resistance:

- Boiler Quality Plates: Built to resist high pressures, making them ideal for applications in boilers and pressure vessels that operate under significant pressure.

- Structural Steel Plates: Not intended for high-pressure environments, as they are designed more for structural integrity rather than pressure resistance.

4. Standard/Grade:

- Boiler Quality Plates: Often meet strict standards like IS 2041 R260 and ASTM A516 to ensure safety and performance under high temperature and pressure conditions.

- Structural Steel Plates: Commonly manufactured to standards such as ASTM A36, IS 2062, and EN 10025, which focus more on structural strength and less on high-pressure or high-temperature performance.

5. Cost:

- Boiler Quality Plates: Typically more expensive due to the higher requirements for quality control, testing, and the ability to withstand extreme conditions.

- Structural Steel Plates: Generally more affordable, as they are designed for less demanding environments and broader applications.

6. Weldability & Formability:

- Boiler Quality Plates: Excellent weldability and formability, allowing them to be easily shaped and welded for complex boiler and pressure vessel designs.

- Structural Steel Plates: Good weldability and formability, but primarily suited for structural applications where complex welding or forming is not as critical.

7. Supplier Specialization:

- Boiler Quality Plates: Supplied by specialized manufacturers who focus on high-grade materials designed to meet rigorous standards for temperature, pressure, and performance.

- Structural Steel Plates: Available from a wide range of suppliers, as they are used in various structural applications and do not require the same level of specialization as boiler quality plates.

Understanding IS 2041 R260 Boiler Plates

The IS 2041 R260 grade is one of the most trusted specifications for boiler and pressure vessel applications in India. Here’s why it stands out:

- Yield Strength: Minimum 260 MPa

- Tensile Strength: 410-530 MPa

- Excellent Toughness: Especially at low temperatures

- Consistent Surface Finish: Ideal for boiler fabrication and welding

This grade is widely demanded by power generation plants, oil and gas refineries, and chemical industries. The strict quality norms ensure safety, which is non-negotiable in pressure-related applications.

Choosing the Right Steel Plate for Your Project

The choice between boiler quality plates and structural steel plates depends entirely on your project’s needs.

Choose Boiler Quality Plates If:

- Your application involves high pressure or steam generation

- You’re working in thermal plants, petrochemical units, or refineries

- Safety standards require compliance with pressure vessel codes

Choose Structural Steel Plates If:

- Your project involves building infrastructure or mechanical frameworks

- Weight-bearing and structural support are more critical than heat or pressure resistance

- Budget constraints are a major concern

When in doubt, consult with experienced boiler quality plates suppliers who understand your industry and can guide you to the right material specifications.

Why Source from Trusted Boiler Quality Plates Suppliers?

Given the critical role of BQ plates in safety-intensive applications, it’s essential to work with reputed boiler quality plates suppliers who:

- Offer certified materials like IS 2041 R260

- Maintain traceability and material testing documentation

- Have a reliable track record of servicing heavy industries

- Offer customized plate sizes, thicknesses, and finishes

Whether you’re a procurement officer, a fabricator, or a project engineer, partnering with the right supplier ensures long-term reliability, compliance, and cost-effectiveness.

Conclusion

Understanding the difference between Boiler Quality Plates and Structural Steel Plates is crucial for selecting the right material for your project. Boiler plates, like those made to IS 2041 R260 standards, are engineered to perform under extreme pressure and temperature conditions, whereas structural plates are ideal for load-bearing applications in construction and general manufacturing.

Before making a purchase, consult with reputed boiler quality plates suppliers who can provide quality assurance, technical support, and timely delivery. Making the right material choice not only ensures safety and efficiency but also contributes to the overall success of your project.