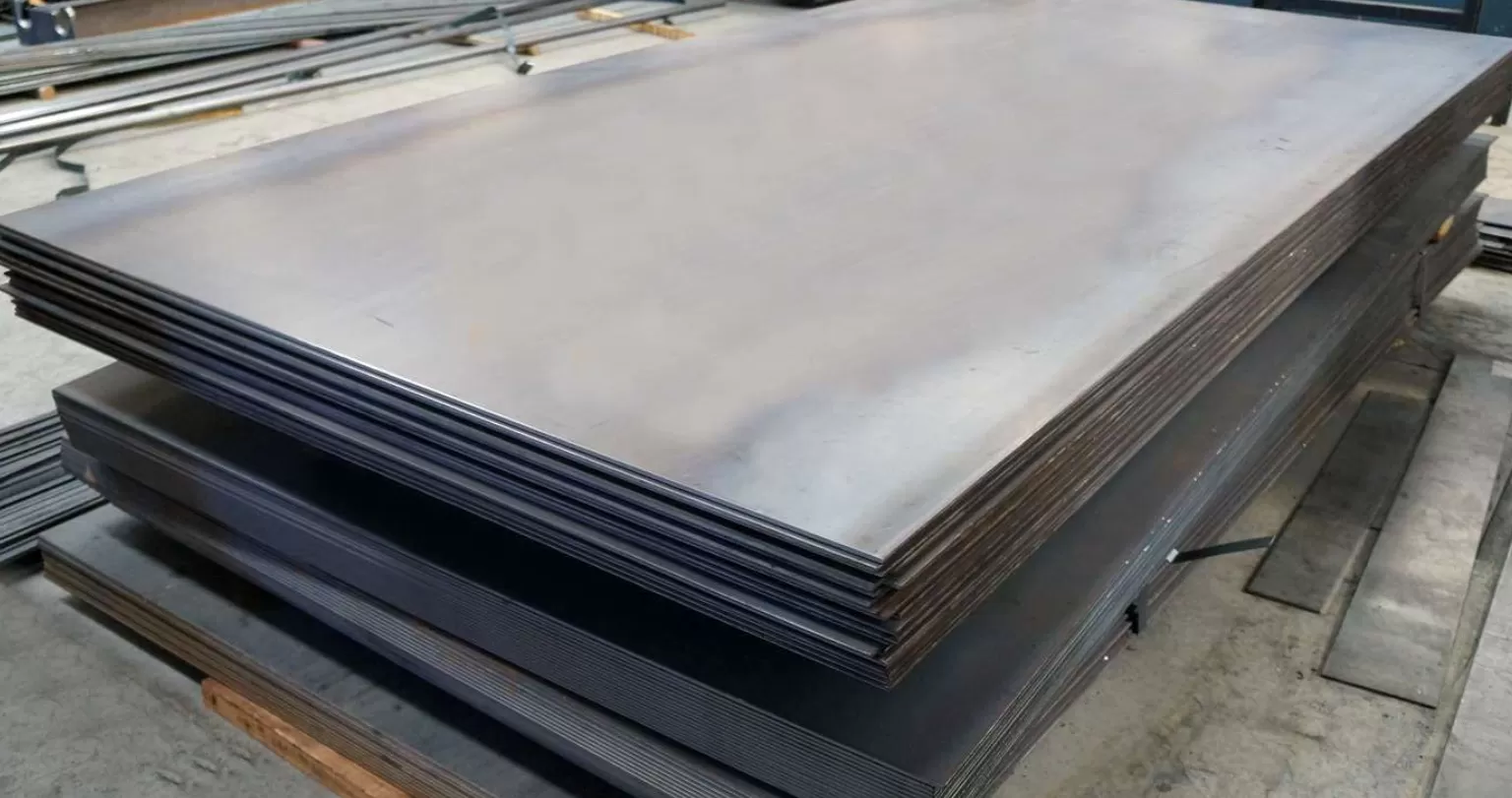

S355J2 Sheets are a popular choice in the structural steel category, known for their exceptional mechanical properties and broad application in various engineering sectors. These sheets belong to the EN 10025-2 standard, a specification that defines hot-rolled structural steel products. Providing an ideal combination of strength, ductility and weldability, S355J2 Sheets are used to a large extent in construction, bridges, offshore installations, and heavy machinery.

This blog takes a closer look at their chemical composition, mechanical strengths, and applications, enabling engineers and procurement specialists to make informed choices.

Understanding Sheets S355J2

S355J2 is a low-carbon manganese steel grade that is not alloyed. It belongs to the S355 family, which also includes S355JR and S355J0, among other variations. S355J2 is unique among them due to its exceptional impact strength. The material is suitable for structures exposed to low temperatures because it has been classified as “J2,” meaning it must withstand a minimum impact energy of 27 Joules and is tested at -20°C.

The sheets made from this grade offer remarkable resistance to brittle fracture, and are ideal for load-bearing structures where durability is a critical concern.

Key Features of S355J2 Sheets

- High Ratio of Strength to Weight

With a high yield strength of about 355 MPa, S355J2 Sheets can withstand a lot of stress before deforming. Due to its strength and lighter structures it can be made without sacrificing their integrity.

- Excellent Weldability

These sheets are weldable by common welding methods without preheating and post-weld heat treatment. This property saves time and money in the fabrication process, which is a necessity in massive construction projects.

- Impact Resistance at Low Temperatures

One of the most important points of S355J2 Sheets is their Charpy V-notch impact strength at -20°C. This makes them ideal for outdoor structures, especially in cold regions where the material must retain toughness under freezing conditions.

- Good Formability and Machinability

Despite their strength, S355J2 Sheets are easy to cut, bend, and machine. This adaptability supports their use in complex structural components, heavy machinery parts, and customized fabrication tasks.

- Resistance to Corrosion (With Coating)

S355J2 Sheets can be galvanized, or coated with protective layers to increase their service life in harsh environments, even though they are not as naturally resistant to corrosion as stainless steel.

Composition of Chemicals

The meticulously balanced chemical composition of S355J2, which normally contains up to 0.22% carbon, 1.60% manganese, 0.55% silicon, and trace amounts of phosphorus and sulfur. Each is limited to 0.030% and is largely responsible for its mechanical performance. This exact description guarantees a perfect combination of strength and ductility with good weldability and machinability. Some other trace elements in small quantities might also be available to improve certain properties, and S355J2 is a very versatile structural steel for various engineering purposes.

Applications of S355J2 Sheets

S355J2 Sheets adaptability enables their use in numerous industries:

Construction, and Infrastructure

These sheets serve as the foundation for numerous structural frameworks, including high-rise buildings, bridges and tunnels. Over many years of use their strength guarantees durability and safety.

- Marine and Offshore Structures

S355J2 Sheets are appropriate for platforms, ships, and other marine installations functioning in sub-zero conditions due to their resistance to brittle failure.

- Heavy Equipment and Machinery

These sheets guarantee performance under dynamic loads, and are used in the construction of frames, cranes, and earthmoving equipment.

- Transportation and Automobiles

Additionally, they are utilised in truck chassis, trailers, and other transportation-related components where durability and portability are essential.

- Wind Towers and Structures for Renewable Energy

S355J2 Sheets offer the required structural integrity against fluctuating loads and environmental conditions in wind turbine towers and solar panel support structures.

Standards and Certifications

S355J2 Sheets comply with the EN 10025-2 standard and often meet additional customer requirements such as:

- CE marking for construction in Europe

- ISO 9001 certification by manufacturers

- Ultrasonic testing (UT) for internal flaws

- Mill test certificates with chemical and mechanical test results

These quality benchmarks assure users of consistent and dependable material performance in demanding applications.

Why Choose S355J2 Sheets?

Choosing S355J2 Sheets means opting for a material that offers:

A superior strength profile compared to many mild steel alternatives

Dependability in low-temperature and high-stress environments

Compatibility with modern fabrication techniques

Long-term cost efficiency due to reduced maintenance and structural resilience

Its adaptability across industries and climate zones makes it one of the most practical steel sheet grades available today.

Conclusion

More than just structural steel, S355J2 sheets are an essential part of modern engineering that blends durability, strength, and flexibility. These sheets provide a reliable framework whether you’re designing offshore structures, building bridges, or producing industrial equipment.

It’s crucial to collaborate with seasoned vendors who provide certified materials that are suited to your particular project requirements. When looking for premium S355J2 Sheets choose wisely and construct with assurance.