Alloy 28 Pipes Supplier

Table Of Content

- What is Alloy 28 Pipes

- Standard Specification For Alloy 28 Pipes

- 28 Alloy Pipes Equivalent Grades

- ASTM B668 Alloy 28 Pipes Types

- Chemical Composition of Alloy 28 Pipes

- Mechanical Properties of Alloy 28 Pipes

- Other Types of Alloy 28 Pipes Ready Stock

- ASME SB668 Alloy 28 Pipes Applications

- Searches Related to Alloy 28 Pipes

- Export Destinations for Alloy 28 Pipes

Alloy 28 Semi Round Pipes, ASTM B668 Alloy 28 Pipes, Alloy 28 Pipes, 1.4563 Pipes, Alloy N08028 Round Pipes, Alloy 28 Large Diameter Pipes, Alloy 1.4563 Pipes, ASME SB 668 Alloy 28 Pipes Supplier in Mumbai, India.

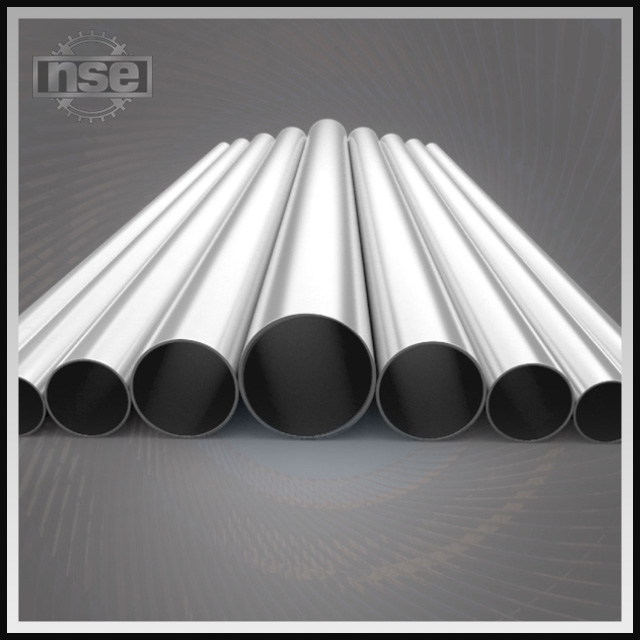

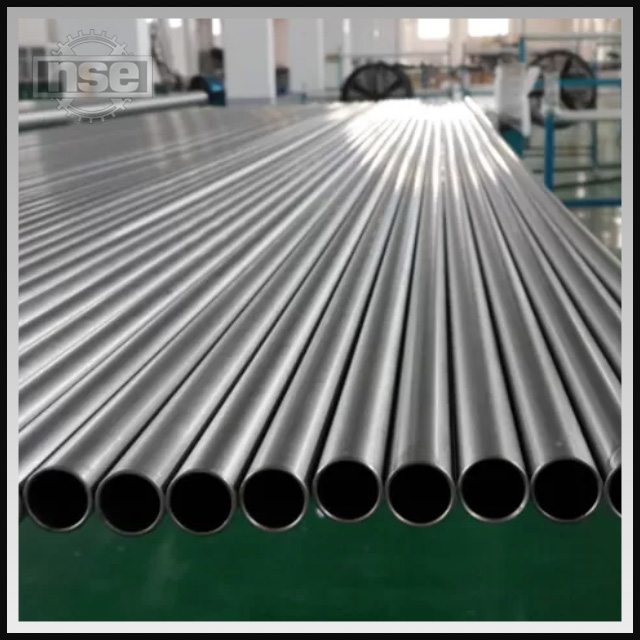

Navgraha Steel & Engg Company have made their presence felt in the market industry strongly Inspite of the growing competition. Setting an example for others is done by us proudly. Alloy 28 pipes refer to varied purposes of industrial use at a time. They are quite famous for their pitting fighting ability. Alloy 28 pipes display fantastic welding ability. Working amongst strong acids is their signature feature. Not getting cracked on the surface is one more additional yet striking feature of Alloy 28 pipes. The outstanding combination of carbon, nickel, silicon, manganese, phosphorous, sulfur, copper, and nitrogen is very compatible and useable. Industries using them find them beneficial. Alloy 28 pipes can fit well into any end of the gadget. Threading, welding, forming processes can be used to attach them to the machines.

These pipes are available in customized and default forms; besides, we also manufacture the different types of these grades. With the help of this grade, we offer the best surface finishing. We offer great specifications such as designs, shapes, sizes, materials, grades, and other specifications. They work reliably with different applications.

Alloy 28 pipes are manufactured using high quality raw materials and tested Alloy 28 Pipes at each production stage to ensure its quality is not compromised. Alloy 28 Pipes is a Stainless Steel Alloy that offers high corrosion resistance in any working environment. These Alloy 28 pipes have great characteristics and attributes that offer good corrosion resistance in strong acids, very good resistance to stress corrosion cracking in hydrogen sulfide (h2s), and chloride-containing environments, very good resistance to intergranular corrosion, high resistance to pitting and crevice corrosion, and good weldability. These are the different attributes of the Alloy 28 pipes that offer great outcomes with the different sorts of applications.

UNS N08028 Pipes, Alloy 28 Seamless Pipes, ASTM B668 Alloy 28 EFW Pipes, Alloy 28 Pipes, Alloy 28 ERW Pipes, Alloy 28 Pipes Stockist, Alloy 28 Pipes price, Grade Alloy 28 Pipes, Alloy 28 Custom Pipes, Alloy 28 Welded Pipes, Alloy 28 Industrial Pipes Manufacturer in Mumbai, India.

Specification of Alloy 28 Pipes

| Specifications | ASTM B668 / ASME SB668 |

| Dimensional specification | ANSI/ASME B36.19M, ANSI/ASME B36.10M |

| Seamless / Welded Pipe Size | 1 / 8″ NB – 24″ NB |

| EFW Pipe Size | 6″ NB – 48″ NB |

| Outside Diameter | 6.00 mm OD up to 914.4 mm OD, Sizes up to 24” NB available Ex-stock, OD Size Steel Tubes available Ex-stock |

| Manufacturing Shapes | Hydraulic, Round, Rectangle, Square, Hex, Honed |

| Manufacturing Techniques | Seamless / Welded / ERW / Fabricated / CDW / 100% X Ray Welded |

| Schedule Thickness Range | SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS |

| Pipes End Types | Plain End, Beveled End, Treaded One End, TBE (Treaded Both Ends) |

| Delivery Condition of Pipe | Annealed and Pickled, Polished, Bright Annealed, Cold Drawn |

| Surface Finish | No.1, No.4, No.8 Mirror Finish, 2B |

| Value Added Services | Cutting, Beveling, Polishing, Threading, Destructive, Non Destructive, Ultrasonic Testing |

Alloy 28 Pipes Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | EN | AFNOR |

| Alloy 28 | 1.4563 | N08028 | X1NiCrMo31-27-4 | Z1NCDU31-27-03 |

Products Range of Alloy 28 Pipes

Seamless Pipes

- ASME SB668 Alloy 28 Seamless Pipe

- Alloy 28 Seamless Pipes

- Alloy 1.4563 Seamless Pipes

- Alloy 28 Seamless Pipes Suppliers

- Alloy 28 Seamless Pipes Exporters

- ASTM B668 Alloy 28 Seamless Pipes

- Alloy 1.4563 Seamless Pipe

- Alloy 1.4563 Seamless Pipes Supplier

- Alloy 28 Seamless Pipes Stockists

- Alloy N08028 Seamless Pipes

- UNS N08028 Seamless Pipes

Welded Pipes

- Alloy 28 Welded Pipe

- Alloy N08028 Welded Pipes

- Alloy 28 Welded Pipes Suppliers

- ASTM B668 Alloy 28 Welded Pipes

- ASME SB668 Alloy 28 Welded Pipe Exporters

- Alloy 1.4563 Welded Pipe

- Alloy 28 Welded Pipes Exporters

- UNS N08028 Welded Pipes

- Alloy 1.4563 Welded Pipe Manufacturer

- Alloy 28 Welded Pipe Stockists

EFW Pipes

- Alloy N08028 Semi Round Pipe

- Alloy 28 Round Pipe

- Alloy 1.4563 Round Pipe Exporter

- Alloy 28 Semi Round Pipes Suppliers

- UNS N08028 Round Pipes

- Alloy N08028 Round Pipes Suppliers

- Alloy 1.4563 Round Pipes

- 1.4563 Alloy Round Pipe

- Alloy 28 Round Pipes Stockist

- Alloy 28 Round Pipes Manufacturer

Round Pipes

- Alloy N08028 Semi Round Pipe

- Alloy 28 Round Pipe

- Alloy 1.4563 Round Pipe Exporter

- Alloy 28 Semi Round Pipes Suppliers

- UNS N08028 Round Pipes

- Alloy N08028 Round Pipes Suppliers

- Alloy 1.4563 Round Pipes

- 1.4563 Alloy Round Pipe

- Alloy 28 Round Pipes Stockist

- Alloy 28 Round Pipes Manufacturer

ERW Pipes

- Alloy 28 Electric Resistance Welded Pipes

- Alloy N08028 ERW Pipes

- Alloy 1.4563 ERW Pipes

- 1.4563 Alloy ERW Pipe

- Alloy 28 Electric-Resistance-Welded Pipes

- Alloy 28 ERW Pipes Suppliers

- Alloy 28 ERW Pipes Exporters

- ASTM B668 Alloy 28 ERW Pipes

- ASME SB668 Alloy 28 ERW Pipe

- Alloy N08028 Electric Resistance Welded Pipe

- UNS N08028 ERW Pipes

- Alloy 28 ERW Pipe

ASTM B668 Alloy 28 Pipes Chemical Composition

| Grade | C | Si | Mn | P | S | Cr | Ni | Mo | Cu |

| Alloy 28 | 0.020 max | 0.6 max | 2.0 max | 0.025 max | 0.010 max | 27.00 | 31 | 3.5 | 1.0 |

Alloy 28 Pipes Mechanical Properties

| Element | Tensile Strength | Yield Strength (0.2%Offset) | Elongation | Hardness |

| Alloy 28 | 500-750 | 220 | 35 % | 230 |

Ready Stock of Alloy 28 Pipes

- Alloy 28 Thin Wall Pipes Supplier in India

- Alloy 28 Heavy Wall Pipe Wholesaler

- UNS N08028 Oval Pipe Supplier

- Alloy 28 High Pressure Pipe Manufacturer

- Alloy 28 Semi Round Pipe Exporters

- Alloy 1.4563 Pipes Exporter

- Alloy 28 Half Round Pipes

- Alloy 28 Pipes Exporter

- Grade Alloy 28 Semi Round Pipes

- Alloy 28 Pipe Supplier

- Alloy N08028 Electropolished Pipes Dealer

- Alloy 28 Welded Pipes Supplier in Mumbai

- Alloy 28 Round Pipe Manufacturer

- Alloy N08028 Electric Resistance Welded Pipes Exporters

- Alloy 28 Round Pipes Supplier

- ASTM B668 Alloy 28 Welded Pipes Stockist

- Alloy 28 Pipe

- Alloy N08028 Custom Pipes

- ASTM B668 Alloy 28 Pipes at Best Price in India

- Alloy 28 Semi Round Pipes Exporter

- Alloy 28 Pipes Dealer in India

- Alloy 28 ERW Pipes Stockist

- ASTM B668 Alloy 28 Heavy Wall Pipe

- Alloy 28 Pipes Supplier in India

- Alloy 28 Large Diameter Round Pipes

- Grade Alloy 28 Cold Drawn Pipe

- Alloy 28 Pipe Manufacturer

- Alloy 28 Pipes Suppliers

- 1.4563 Alloy Pipes

- Alloy 28 Pipes Stockists

- Alloy 1.4563 Pipes Suppliers

- Alloy 1.4563 Seamless Pipes Exporter

- Alloy 28 Electric-Fusion-Welded Pipes Stockists

ASME SB668 Alloy 28 Pipes Applications and Uses